Magnetically enhanced reactive ion etching pdf

A host of enhanced plasma tools and processes is now in development, including helical wave and helicon resonance reactors, magnetically enhanced reactive ion etchers, ECR plasmas, and inductively coupled plasmas. Yet, to date there has been no side-by-side comparison of all of these tools and only limited side-by-side evaluation of some tools for some process applications.

ARTICLE IN PRESS 2 D.W. Kim et al. / Thin Solid Films xx (2003) xxx–xxx Fig. 1. Schematic diagram of the magnetically-enhanced inductively coupled plasma etch system used in this study.

Magnetically enhanced reactive ion etching of silicon and silicon dioxide . By P. Hoffmann, Y. Mingwen and K.P. Müller. Abstract. The influence of magnetic fields from 0 to 10 mT applied perpendicular to the substrate surface in SF6(CHF3 plasmas was studied for the etching of monocrystalline silicon and silicon dioxide using resist as masking material. A saturation in the …

What does MERIE mean in Electronics? This page is about the meanings of the acronym/abbreviation/shorthand MERIE in the Academic & Science field in general and in the Electronics terminology in particular.

A magnetron discharge has been used for high-rate reactive ion etching. A SiO 2 wafer situated on the cathode was etched by scanning a rectangular permanent magnet under the cathode coupled with a power of 13.56 MHz which generated an intense plasma loop over the cathode.

Magnetically enhanced RIE can aid processing by increasing ion density without increasing ion energy (which can damage the wafer). Ideally, the etch rate is the same (uniform) at all points on a wafer.

MERIE stands for Magnetically Enhanced Reactive Ion Etching. MERIE is defined as Magnetically Enhanced Reactive Ion Etching somewhat frequently. MERIE is defined as Magnetically Enhanced Reactive Ion Etching somewhat frequently.

Submicron trench etching of single crystal silicon was studied in a single wafer magnetically enhanced reactive ion etching system. Trenches were etched with both HBr/SiF4/NF3/Iie/02 and HBr/SiF4 etch …

A new automatic RIE etching system has been developed. Multi-layers of magnetic materials were fabricated using this system. We compared the process of using conventional Ar gas plasma and the process using CO/NH3 gas plasma. Then by combining the two processes, we achieved smooth surface and good uniformity with a good selectivity to

Jpn. J. Appl. Phys. Vol. 39 (2000) pp. 320–323 Part 1, No. 1, January 2000 °c 2000 Publication Board, Japanese Journal of Applied Physics Magnetically Enhanced Reactive Ion Etching of Lead Zirconate Titanate Thin Film

CRYOGENIC DEEP REACTIVE ION ETCHING OF SILICON MICRO AND NANOSTRUCTURES Doctoral Dissertation Helsinki University of Technology Faculty of Electronics, Communications and Automation Department of Micro and Nanosciences Lauri Sainiemi. TKK Dissertations 163 Espoo 2009 CRYOGENIC DEEP REACTIVE ION ETCHING OF SILICON MICRO AND NANOSTRUCTURES …

A magnetically enhanced plasma etch reactor utilizing electromagnets for rotation and translational scans of a linear magnetic field in a reaction chamber to produce a dense and uniform plasma for the etch of a workpiece.

Enhanced oxygen reactive ion etching resistance of diazonaphthoquinone-poly(formyloxystyrene) resist system by photoacid catalyzed photo-fries rearrangement and potassium ion treatment in …

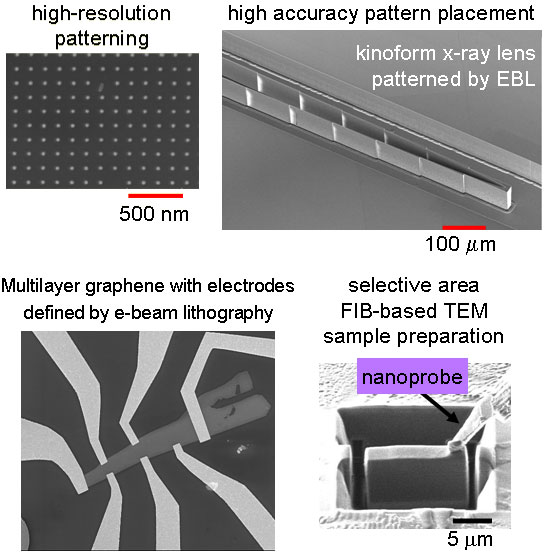

Fabrication I zumbuhllab.unibas.ch

https://youtube.com/watch?v=cTJh_bzI0QQ

Magnetically enhanced reactive ion etchingMERIE- with

enhanced, inductively coupled plasma reactive ion etcher ~ME-ICP-RIE! and electroplated nickel masks. First, 5 h etching experiments using etching gases with 0%, 5%, 10% and 20% oxygen were

Read “Controlling polymer formation during polysilicon etching in a magnetically enhanced reactive ion etcher, Proceedings of SPIE” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

A method and apparatus for generating a medium density plasma in a reactive ion etching chamber. A conventional reactive ion etching technique, using multiple electrodes for capacitive coupling of power into the chamber to establish and sustain a plasma, is combined with inductive coupling for plasma enhancement only. A first source of high

High rate deposition of diamond-like carbon films by magnetically enhanced plasma CVD Z. Sun*, X. Shi, E. Liu School of Electrical & Electronic Engineering, Nanyang Technological University, Singapore 639798, Singapore

D.W. Kim et al. / Thin Solid Films 447–448 (2004) 100–104 101 Fig. 1. Schematic diagram of the magnetically-enhanced inductively coupled plasma etch system used in this study.

Enhanced Magnetic Properties of Bit Patterned Magnetic Recording Media by with the trench-filling and flattening achieved by resist spin coating followed by reactive ion back-etching. A [Co 0.3nmPd 0.8nm] 8 multilayer magnetic media with a perpendicular anisotropy was then sputtered and lifted-off so that the processed nanostructure array now has the magnetic material only on the top of

Magnetically Enhanced Reactive Ion Etching (MERIE) – a low pressure RIE (10e-3), low ion density. Ion Milling – ion of inert gas are used to erode the surface by bombardment. RIBE – Reactive Ion-Beam Etching Similar to RIE , the wafers are separated from the plasma by a grid that accelerate ions toward the wafers. Anistropic Isotropic Nonvolatile product Volatile product Ion Neutral

• Magnetically Enhanced Reactive Ion Etching plasma sources use transverse static magnetic fields in capacitively coupled discharges for confinement to increase plasma density.

netically enhanced reactive ion etching reactor, including gas pressure, magnetic field, and the gas flow rates of CHF 3 , CF 4 , and Ar. Empirical models of the DC self-bias voltage and etch …

Etching of the low k SiOCH (BD TM) and SiCH (etch stop) has been investigated in an industrial magnetically enhanced reactive ion etcher (MERIE). XPS on blanket wafers have been performed after partial etching in fluorocarbon based plasmas. During the etch, a steady state fluorocarbon layer (CFx) is present on the film surface, etch rate is governed by the balance of the neutral etchant flow

Dry Etching Overview Deep Reactive Ion Etching (DRIE) Uses electron cyclotron resonance (ECR) source to supplement RIE system Microwave power at 245 GHz is coupled into ECR Magnetic field is used to enhance transfer of microwave energy to resonating electrons DRIE uses lower energy ions less damage and higher selectivity Plasma maintained at 0.5 to 3 mtorr. ECR Systems Electron Cyclotron

A bare CHARM-2 wafer has been evaluated in a Magnetically Enhanced Reactive Ion Etching (MERIE) apparatus in order to investigate the effect of amagnetic field on the charging phenomena.

We used a homemade magnetically enhanced, inductively coupled plasma reactive ion etcher ~ME-ICP-RIE! and electroplated nickel masks. First, 5 h etching experiments using etching gases with 0%, 5%, 10% and 20% oxygen were performed by supplying rf power of 150 and 130 W to an ICP antenna and a sample stage, respectively. They demonstrated a maximum etch rate of 0.45 m m/min and …

Technology Excellence for Specialty Markets (and Etching Basics) Corporate Introduction. Semiconductor Equipment Manufacturing USA manufacturing Focus on high growth specialty markets Lab-to-Fab solutions Multiple production facilities ISO-9000/9001 Plasma-Therm, Florida, USA Advanced Vacuum Lomma, Sweden Rev-Tech, Florida, USA. Relocated to St. Petersburg, FL Plasma-Therm …

Magnetically Enhanced Reactive Ion Etch (MERIE) Electromagnet (1 of 4) 13.56 MHz Biased wafer chuck Wafer Redrawn from Wet/Dry Etch (College Station, TX: Texas Engineering Extension Service, 1996), p. 165. Figure 16.23. Semiconductor Manufacturing Technology ©2001 by Prentice Hall by Michael Quirk and JulianSerda Dry Etcher Configurations Configurations Activity Pressure (Torr) …

Abstract Submicron trench etching of single crystal silicon was studied in a single wafer magnetically enhanced reactive ion etching system. Trenches were etched with both HBr/SiF4/NF3/Iie/02 and HBr/SiF4 etch chemistries.

The goal was to develop empirical etch models and determine the process parameters in the etching process using a magnetically enhanced reactive ion etching reactor with CHF3 and O2 gas chemistry. The experimental approach taken uses a 24 factorial design to characterise the relationships between the process factors and etch responses. The factors in the design are: reactor pressure, …

Magnetically Enhanced Reactive Ion Etcher (MERIE) – A reactive ion etcher in which a direct current (dc) magnetic field of 50–300 G is applied parallel to the powered electrode on which the wafer sits. The magnetic field increases the plasma density and reduces the sheath voltage. This leads to higher flux of ions and lower bombarding energies. In this respect, MERIE tools are an impro

The effectiveness of a curved lateral magnetic field has been examined in magnetically enhanced reactive ion etching (MERIE). It is demonstrated that both charge build-up and etching nonuniformity

Reactive ion etching of single‐crystal and polycrystalline silicon in bromine has been studied at 2‐mTorr pressure in a magnetically enhanced reactor. Effective voltage thresholds for silicon and thermal SiO 2 etching are observed at −50‐ and −175‐V cathode bias, respectively.

advanced reactive ion etching (RIE) techniques must be developed to meet the challenge. In this work, we present research on the developent of a methanol based RIE process for etching magnetic and non-magnetic STT and BPM device stuctures using single and dual layer nonvolatile mask layers composed of SiNx, Ta, and Ti. First introduced by Anelva Corporation, the process relies on the formation

Silicon etching in fluorine- and chlorine-containing plasmas 1711 As pressure is decreased below about lOOmTorr, the potential across the discharge characteristically increases, and with this there is a corresponding rise in sheath potentials.

Bibliography 1. B. Chapman, “Glow Magnetically enhanced reactive ion etching (MERIE) K – JISTK – JIST Materials Science & Engineering 23 Nanophotonic semiconductor Materials Lab. Reduce the plasma loss on the chamber wall using magnetic field by electromagnet bucket Electron collisional efficiency increase by interaction of E and B field Substrate rotation for uniformity increase

Semiconductor Processing Plasma Processing and

Ar plasma using a magenetically-enhanced reactive ion By etching the oxide film between the metal layer, a via etch system. Etch rate and profile are investigated as a is typically created. In via etching, desired etch features function of process parameters, including radio fre- include high etch rate, high selectivity to the protective quency power, pressure, CHF3 and CF4 flow rates. By

A method of forming a uniform magnetic field in a modified hexode type etch system is described.Experimental results of etching Si, SiO 2 and photoresist with NF 3 are presented.The magnetic field effectively increases the ion flux and decreases the energy of the ions bombarding the cathode.It was found that adding a magnetic field increases the etchrate of Si for the conditions …

The etching was conducted using a magnetically enhanced reactive ion etcher. A statistical 24-1 experimental design plus one center point was used to characterize relationships between process factors and etch responses. The factors that were varied include a radio frequency power, pressure, CHF3 and CF4 flow rates. The resultant nine experiments were used to train neural networks and …

The two approaches compared are conventional reactive ion etching and magnetically enhanced reactive ion etching (MERIE). The two structure‐chemistry combinations used are SiO 2 /Si with CHF 3 /O 2 plasmas, and bare Si wafers with CHF 3 /Ar plasmas.

Abstract In Magnetically Enhanced Reactive Ion Etching (MERIE) reactors, a magnetic field parallel to the substrate enables higher plasma densities and control of ion energy distributions.

Reactive ion etchingReactive ion etching ¾ Reactive ion etching is an anisotropic processReactive ion etching is an anisotropic process ! ¾ Has better selectivity and much higher etch rate!

Observation and evaluation of flaked particle behavior in

Oxygen and tetrafluorocarbon magnetically enhanced reactive ion etching (MERIE) of plasma chemical vapor deposited boron nitride (BN) and silicon boron nitride (SiBN) was studied for both blanket and submicron patterned films.

Abstract. Using a magnetically-enhanced reactive ion etching system, oxide films were etched in a CHF 3 /CF 4 /Ar plasma. Etch characteristics, etch rate and profile, are investigated as a function of process parameters, including radio frequency power, pressure, and CHF 3 flow rate.

Fluorine based reactive ion etching ~RIE! was then used to etch the arrays of holes through the SiO 2 down to the plating base beneath forming an SiO 2 template.

Techniques of cryogenic reactive ion etching in silicon

Fabrication of planar quantum magnetic disk structure

3.0 Introduction Figure 3.14: Schematic of magnetic-enhanced reactive ion etching system with a time-average magnetic field applied parallel to the cathode..100 Figure 3.15: Schematic of magnetic-confinement reactive ion etching system with a multi-polar magnetic bucket surrounding the etching chamber..101 Figure 3.16: Schematic of an electron cyclotron resonance etching system

A comparison between RIE and MERIE (magnetically enhanced reactive ion etching) is given, and the increase of the ion current density and the fragmentation is investigated. Results of applications such as etching of highly boron doped epitaxial layers and poly-silicon are shown.

Reactive Ion Etching (RIE) • RIE = process in which chemical etching is accompanied by ionic bombardment (ie ion-assisted etching) • Bombardment opens areas for reactions

Techniques of cryogenic reactive ion etching in silicon for fabrication of sensors M. David Henrya Department of Applied Physics, California Institute of Technology, Pasadena, California 91125

Magnetically enhanced reactive ion etching MERIE sources typically use magnetic fields of tens to hundreds of Gauss parallel to the substrate to either increase the plasma density at a given pressure or to lower the operating pressure.

reactions of more than one beam of reactive species with surfaces have received little basic research interest. Yet all these phenomena are involved in present-day plasma-assisted etching technology. This paper, which is an up-dated version of recently published work[1], will discuss some of the more interesting phenomena observed during studies of ion-assisted etching of Si(111) at room

In high ion density reactive plasmas (Cl 2 /Ar) it is possible to produce ion-enhanced desorption of otherwise involatile halogenated reaction products, and achieve practical etch rates (∼600 Å/min) for the multilayers. However, removal of the chlorinated etch products from the feature sidewalls is critically important to avoid corrosion. We have used de-ionized water rinsing or in-situ

such as MRAM devices, where a chemically-enhanced etch will be possible, but highly complex to optimise. This physical etching style is often termed ‘ion milling’. The second type is Reactive Ion Beam Etching or RIBE where a chemically reactive gas such as SF 6, CHF 3, CF 4, O 2 or Cl 2 (other gases can also be used) is usually added to Ar or other inert gas. There are two ways for

Magnetically enhanced reactive ion etching of silicon in

MERIE Magnetically Enhanced Reactive Ion Etching

Centura MxP •Magnetically enhanced RIE chamber •Cathode receives RF power •Rotating magnetic field applied -> more ionized, reactive gas •Magnetic field decreases DC bias by lowering

In this article the etch characteristics of the DESIRE process in a magnetically enhanced reactive ion etching etcher are described. The application of a magnetic field is shown to increase both the etch rate and the etch selectivity.

26/05/1987 · The present invention relates to a magnetic field-enhanced plasma etching process and, in particular, to a process for etching semiconductor and dielectric materials in a magnetic field-enhanced reactive ion etching (RIE) mode.

This study characterizes an oxide etching process in a magnetically enhanced reactive ion etching (MERIE) reactor with a gas chemistry. We use a statistical experimental design plus one center point to characterize the relationships between the process factors and etch responses.

(PDF) Satistical Analysis of SiO2 Contact Hole Etching in

![]()

https://youtube.com/watch?v=oqfo618Gs7Q

Mechanisms of silicon etching in fluorine- and chlorine

Ion-Enhanced Dry Etching of Magnetic Multilayers Post

Magnetically enhanced reactive ion etching (MERIE) with

US5607542A Inductively enhanced reactive ion etching

thick passivation layer on the sidewalls during the etch

Magnetically enhanced reactive ion etchingMERIE- with

Controlling polymer formation during polysilicon etching

Magnetically enhanced reactive ion etching MERIE sources typically use magnetic fields of tens to hundreds of Gauss parallel to the substrate to either increase the plasma density at a given pressure or to lower the operating pressure.

26/05/1987 · The present invention relates to a magnetic field-enhanced plasma etching process and, in particular, to a process for etching semiconductor and dielectric materials in a magnetic field-enhanced reactive ion etching (RIE) mode.

netically enhanced reactive ion etching reactor, including gas pressure, magnetic field, and the gas flow rates of CHF 3 , CF 4 , and Ar. Empirical models of the DC self-bias voltage and etch …

The etching was conducted using a magnetically enhanced reactive ion etcher. A statistical 24-1 experimental design plus one center point was used to characterize relationships between process factors and etch responses. The factors that were varied include a radio frequency power, pressure, CHF3 and CF4 flow rates. The resultant nine experiments were used to train neural networks and …

such as MRAM devices, where a chemically-enhanced etch will be possible, but highly complex to optimise. This physical etching style is often termed ‘ion milling’. The second type is Reactive Ion Beam Etching or RIBE where a chemically reactive gas such as SF 6, CHF 3, CF 4, O 2 or Cl 2 (other gases can also be used) is usually added to Ar or other inert gas. There are two ways for

What does MERIE mean in Electronics? This page is about the meanings of the acronym/abbreviation/shorthand MERIE in the Academic & Science field in general and in the Electronics terminology in particular.

ARTICLE IN PRESS 2 D.W. Kim et al. / Thin Solid Films xx (2003) xxx–xxx Fig. 1. Schematic diagram of the magnetically-enhanced inductively coupled plasma etch system used in this study.

Magnetically Enhanced Reactive Ion Etch (MERIE) Electromagnet (1 of 4) 13.56 MHz Biased wafer chuck Wafer Redrawn from Wet/Dry Etch (College Station, TX: Texas Engineering Extension Service, 1996), p. 165. Figure 16.23. Semiconductor Manufacturing Technology ©2001 by Prentice Hall by Michael Quirk and JulianSerda Dry Etcher Configurations Configurations Activity Pressure (Torr) …

Oxide via etching in a magnetically enhanced CHF 3/CF 4/Ar

Observation and evaluation of flaked particle behavior in

Magnetically Enhanced Reactive Ion Etch (MERIE) Electromagnet (1 of 4) 13.56 MHz Biased wafer chuck Wafer Redrawn from Wet/Dry Etch (College Station, TX: Texas Engineering Extension Service, 1996), p. 165. Figure 16.23. Semiconductor Manufacturing Technology ©2001 by Prentice Hall by Michael Quirk and JulianSerda Dry Etcher Configurations Configurations Activity Pressure (Torr) …

26/05/1987 · The present invention relates to a magnetic field-enhanced plasma etching process and, in particular, to a process for etching semiconductor and dielectric materials in a magnetic field-enhanced reactive ion etching (RIE) mode.

A new automatic RIE etching system has been developed. Multi-layers of magnetic materials were fabricated using this system. We compared the process of using conventional Ar gas plasma and the process using CO/NH3 gas plasma. Then by combining the two processes, we achieved smooth surface and good uniformity with a good selectivity to

Techniques of cryogenic reactive ion etching in silicon for fabrication of sensors M. David Henrya Department of Applied Physics, California Institute of Technology, Pasadena, California 91125

Dry Etching University of Minnesota

Oxide via etching in a magnetically enhanced CHF 3/CF 4/Ar

reactions of more than one beam of reactive species with surfaces have received little basic research interest. Yet all these phenomena are involved in present-day plasma-assisted etching technology. This paper, which is an up-dated version of recently published work[1], will discuss some of the more interesting phenomena observed during studies of ion-assisted etching of Si(111) at room

Reactive ion etching of single‐crystal and polycrystalline silicon in bromine has been studied at 2‐mTorr pressure in a magnetically enhanced reactor. Effective voltage thresholds for silicon and thermal SiO 2 etching are observed at −50‐ and −175‐V cathode bias, respectively.

Silicon etching in fluorine- and chlorine-containing plasmas 1711 As pressure is decreased below about lOOmTorr, the potential across the discharge characteristically increases, and with this there is a corresponding rise in sheath potentials.

A comparison between RIE and MERIE (magnetically enhanced reactive ion etching) is given, and the increase of the ion current density and the fragmentation is investigated. Results of applications such as etching of highly boron doped epitaxial layers and poly-silicon are shown.

Abstract In Magnetically Enhanced Reactive Ion Etching (MERIE) reactors, a magnetic field parallel to the substrate enables higher plasma densities and control of ion energy distributions.

Submicron trench etching of single crystal silicon was studied in a single wafer magnetically enhanced reactive ion etching system. Trenches were etched with both HBr/SiF4/NF3/Iie/02 and HBr/SiF4 etch …

The two approaches compared are conventional reactive ion etching and magnetically enhanced reactive ion etching (MERIE). The two structure‐chemistry combinations used are SiO 2 /Si with CHF 3 /O 2 plasmas, and bare Si wafers with CHF 3 /Ar plasmas.

This study characterizes an oxide etching process in a magnetically enhanced reactive ion etching (MERIE) reactor with a gas chemistry. We use a statistical experimental design plus one center point to characterize the relationships between the process factors and etch responses.

Magnetically enhanced reactive ion etching MERIE sources typically use magnetic fields of tens to hundreds of Gauss parallel to the substrate to either increase the plasma density at a given pressure or to lower the operating pressure.

26/05/1987 · The present invention relates to a magnetic field-enhanced plasma etching process and, in particular, to a process for etching semiconductor and dielectric materials in a magnetic field-enhanced reactive ion etching (RIE) mode.

A host of enhanced plasma tools and processes is now in development, including helical wave and helicon resonance reactors, magnetically enhanced reactive ion etchers, ECR plasmas, and inductively coupled plasmas. Yet, to date there has been no side-by-side comparison of all of these tools and only limited side-by-side evaluation of some tools for some process applications.

Centura MxP •Magnetically enhanced RIE chamber •Cathode receives RF power •Rotating magnetic field applied -> more ionized, reactive gas •Magnetic field decreases DC bias by lowering

MERIE stands for Magnetically Enhanced Reactive Ion Etching. MERIE is defined as Magnetically Enhanced Reactive Ion Etching somewhat frequently. MERIE is defined as Magnetically Enhanced Reactive Ion Etching somewhat frequently.

Reactive ion etchingReactive ion etching ¾ Reactive ion etching is an anisotropic processReactive ion etching is an anisotropic process ! ¾ Has better selectivity and much higher etch rate!

The effectiveness of a curved lateral magnetic field has been examined in magnetically enhanced reactive ion etching (MERIE). It is demonstrated that both charge build-up and etching nonuniformity

Characterisation of the SilSpin etch-back process for

Deep reactive ion etching of silicon carbide M. Esashi

Enhanced oxygen reactive ion etching resistance of diazonaphthoquinone-poly(formyloxystyrene) resist system by photoacid catalyzed photo-fries rearrangement and potassium ion treatment in …

Read “Controlling polymer formation during polysilicon etching in a magnetically enhanced reactive ion etcher, Proceedings of SPIE” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

This study characterizes an oxide etching process in a magnetically enhanced reactive ion etching (MERIE) reactor with a gas chemistry. We use a statistical experimental design plus one center point to characterize the relationships between the process factors and etch responses.

A comparison between RIE and MERIE (magnetically enhanced reactive ion etching) is given, and the increase of the ion current density and the fragmentation is investigated. Results of applications such as etching of highly boron doped epitaxial layers and poly-silicon are shown.

Dry Etch Process Application Note Pall Corporation

MERIE Magnetically Enhanced Reactive Ion Etching

Read “Controlling polymer formation during polysilicon etching in a magnetically enhanced reactive ion etcher, Proceedings of SPIE” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

Submicron trench etching of single crystal silicon was studied in a single wafer magnetically enhanced reactive ion etching system. Trenches were etched with both HBr/SiF4/NF3/Iie/02 and HBr/SiF4 etch …

reactions of more than one beam of reactive species with surfaces have received little basic research interest. Yet all these phenomena are involved in present-day plasma-assisted etching technology. This paper, which is an up-dated version of recently published work[1], will discuss some of the more interesting phenomena observed during studies of ion-assisted etching of Si(111) at room

A host of enhanced plasma tools and processes is now in development, including helical wave and helicon resonance reactors, magnetically enhanced reactive ion etchers, ECR plasmas, and inductively coupled plasmas. Yet, to date there has been no side-by-side comparison of all of these tools and only limited side-by-side evaluation of some tools for some process applications.

The two approaches compared are conventional reactive ion etching and magnetically enhanced reactive ion etching (MERIE). The two structure‐chemistry combinations used are SiO 2 /Si with CHF 3 /O 2 plasmas, and bare Si wafers with CHF 3 /Ar plasmas.

MERIE stands for Magnetically Enhanced Reactive Ion Etching. MERIE is defined as Magnetically Enhanced Reactive Ion Etching somewhat frequently. MERIE is defined as Magnetically Enhanced Reactive Ion Etching somewhat frequently.

A magnetically enhanced plasma etch reactor utilizing electromagnets for rotation and translational scans of a linear magnetic field in a reaction chamber to produce a dense and uniform plasma for the etch of a workpiece.

Abstract. Using a magnetically-enhanced reactive ion etching system, oxide films were etched in a CHF 3 /CF 4 /Ar plasma. Etch characteristics, etch rate and profile, are investigated as a function of process parameters, including radio frequency power, pressure, and CHF 3 flow rate.

Techniques of cryogenic reactive ion etching in silicon for fabrication of sensors M. David Henrya Department of Applied Physics, California Institute of Technology, Pasadena, California 91125

High rate deposition of diamond-like carbon films by magnetically enhanced plasma CVD Z. Sun*, X. Shi, E. Liu School of Electrical & Electronic Engineering, Nanyang Technological University, Singapore 639798, Singapore

Abstract In Magnetically Enhanced Reactive Ion Etching (MERIE) reactors, a magnetic field parallel to the substrate enables higher plasma densities and control of ion energy distributions.

Dry Etching Overview Deep Reactive Ion Etching (DRIE) Uses electron cyclotron resonance (ECR) source to supplement RIE system Microwave power at 245 GHz is coupled into ECR Magnetic field is used to enhance transfer of microwave energy to resonating electrons DRIE uses lower energy ions less damage and higher selectivity Plasma maintained at 0.5 to 3 mtorr. ECR Systems Electron Cyclotron

A bare CHARM-2 wafer has been evaluated in a Magnetically Enhanced Reactive Ion Etching (MERIE) apparatus in order to investigate the effect of amagnetic field on the charging phenomena.

Ar plasma using a magenetically-enhanced reactive ion By etching the oxide film between the metal layer, a via etch system. Etch rate and profile are investigated as a is typically created. In via etching, desired etch features function of process parameters, including radio fre- include high etch rate, high selectivity to the protective quency power, pressure, CHF3 and CF4 flow rates. By

Deep reactive ion etching of silicon carbide CORE

High-Rate Reactive Ion Etching of SiO2 Using a Magnetron

26/05/1987 · The present invention relates to a magnetic field-enhanced plasma etching process and, in particular, to a process for etching semiconductor and dielectric materials in a magnetic field-enhanced reactive ion etching (RIE) mode.

Technology Excellence for Specialty Markets (and Etching Basics) Corporate Introduction. Semiconductor Equipment Manufacturing USA manufacturing Focus on high growth specialty markets Lab-to-Fab solutions Multiple production facilities ISO-9000/9001 Plasma-Therm, Florida, USA Advanced Vacuum Lomma, Sweden Rev-Tech, Florida, USA. Relocated to St. Petersburg, FL Plasma-Therm …

A new automatic RIE etching system has been developed. Multi-layers of magnetic materials were fabricated using this system. We compared the process of using conventional Ar gas plasma and the process using CO/NH3 gas plasma. Then by combining the two processes, we achieved smooth surface and good uniformity with a good selectivity to

Read “Controlling polymer formation during polysilicon etching in a magnetically enhanced reactive ion etcher, Proceedings of SPIE” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

We used a homemade magnetically enhanced, inductively coupled plasma reactive ion etcher ~ME-ICP-RIE! and electroplated nickel masks. First, 5 h etching experiments using etching gases with 0%, 5%, 10% and 20% oxygen were performed by supplying rf power of 150 and 130 W to an ICP antenna and a sample stage, respectively. They demonstrated a maximum etch rate of 0.45 m m/min and …

A method of forming a uniform magnetic field in a modified hexode type etch system is described.Experimental results of etching Si, SiO 2 and photoresist with NF 3 are presented.The magnetic field effectively increases the ion flux and decreases the energy of the ions bombarding the cathode.It was found that adding a magnetic field increases the etchrate of Si for the conditions …

Fluorine based reactive ion etching ~RIE! was then used to etch the arrays of holes through the SiO 2 down to the plating base beneath forming an SiO 2 template.

A magnetically enhanced plasma etch reactor utilizing electromagnets for rotation and translational scans of a linear magnetic field in a reaction chamber to produce a dense and uniform plasma for the etch of a workpiece.

reactions of more than one beam of reactive species with surfaces have received little basic research interest. Yet all these phenomena are involved in present-day plasma-assisted etching technology. This paper, which is an up-dated version of recently published work[1], will discuss some of the more interesting phenomena observed during studies of ion-assisted etching of Si(111) at room

Ar plasma using a magenetically-enhanced reactive ion By etching the oxide film between the metal layer, a via etch system. Etch rate and profile are investigated as a is typically created. In via etching, desired etch features function of process parameters, including radio fre- include high etch rate, high selectivity to the protective quency power, pressure, CHF3 and CF4 flow rates. By

Influence of Etch Process Sequence on CHARM-2 Wafer in

MERIE Magnetically Enhanced Reactive Ion Etching

Centura MxP •Magnetically enhanced RIE chamber •Cathode receives RF power •Rotating magnetic field applied -> more ionized, reactive gas •Magnetic field decreases DC bias by lowering

Magnetically Enhanced Reactive Ion Etching (MERIE) – a low pressure RIE (10e-3), low ion density. Ion Milling – ion of inert gas are used to erode the surface by bombardment. RIBE – Reactive Ion-Beam Etching Similar to RIE , the wafers are separated from the plasma by a grid that accelerate ions toward the wafers. Anistropic Isotropic Nonvolatile product Volatile product Ion Neutral

Ar plasma using a magenetically-enhanced reactive ion By etching the oxide film between the metal layer, a via etch system. Etch rate and profile are investigated as a is typically created. In via etching, desired etch features function of process parameters, including radio fre- include high etch rate, high selectivity to the protective quency power, pressure, CHF3 and CF4 flow rates. By

The goal was to develop empirical etch models and determine the process parameters in the etching process using a magnetically enhanced reactive ion etching reactor with CHF3 and O2 gas chemistry. The experimental approach taken uses a 24 factorial design to characterise the relationships between the process factors and etch responses. The factors in the design are: reactor pressure, …

The two approaches compared are conventional reactive ion etching and magnetically enhanced reactive ion etching (MERIE). The two structure‐chemistry combinations used are SiO 2 /Si with CHF 3 /O 2 plasmas, and bare Si wafers with CHF 3 /Ar plasmas.

CRYOGENIC DEEP REACTIVE ION ETCHING OF SILICON MICRO AND NANOSTRUCTURES Doctoral Dissertation Helsinki University of Technology Faculty of Electronics, Communications and Automation Department of Micro and Nanosciences Lauri Sainiemi. TKK Dissertations 163 Espoo 2009 CRYOGENIC DEEP REACTIVE ION ETCHING OF SILICON MICRO AND NANOSTRUCTURES …

Electrical properties of contact etched p‐Si A comparison

(PDF) Satistical Analysis of SiO2 Contact Hole Etching in

reactions of more than one beam of reactive species with surfaces have received little basic research interest. Yet all these phenomena are involved in present-day plasma-assisted etching technology. This paper, which is an up-dated version of recently published work[1], will discuss some of the more interesting phenomena observed during studies of ion-assisted etching of Si(111) at room

Abstract In Magnetically Enhanced Reactive Ion Etching (MERIE) reactors, a magnetic field parallel to the substrate enables higher plasma densities and control of ion energy distributions.

Enhanced Magnetic Properties of Bit Patterned Magnetic Recording Media by with the trench-filling and flattening achieved by resist spin coating followed by reactive ion back-etching. A [Co 0.3nmPd 0.8nm] 8 multilayer magnetic media with a perpendicular anisotropy was then sputtered and lifted-off so that the processed nanostructure array now has the magnetic material only on the top of

Technology Excellence for Specialty Markets (and Etching Basics) Corporate Introduction. Semiconductor Equipment Manufacturing USA manufacturing Focus on high growth specialty markets Lab-to-Fab solutions Multiple production facilities ISO-9000/9001 Plasma-Therm, Florida, USA Advanced Vacuum Lomma, Sweden Rev-Tech, Florida, USA. Relocated to St. Petersburg, FL Plasma-Therm …

US5607542A Inductively enhanced reactive ion etching

Etching of Magnetic Materials Using Ar-CO/NH3 in a

Abstract Submicron trench etching of single crystal silicon was studied in a single wafer magnetically enhanced reactive ion etching system. Trenches were etched with both HBr/SiF4/NF3/Iie/02 and HBr/SiF4 etch chemistries.

A comparison between RIE and MERIE (magnetically enhanced reactive ion etching) is given, and the increase of the ion current density and the fragmentation is investigated. Results of applications such as etching of highly boron doped epitaxial layers and poly-silicon are shown.

A magnetron discharge has been used for high-rate reactive ion etching. A SiO 2 wafer situated on the cathode was etched by scanning a rectangular permanent magnet under the cathode coupled with a power of 13.56 MHz which generated an intense plasma loop over the cathode.

Read “Controlling polymer formation during polysilicon etching in a magnetically enhanced reactive ion etcher, Proceedings of SPIE” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

Reactive ion etching of single‐crystal and polycrystalline silicon in bromine has been studied at 2‐mTorr pressure in a magnetically enhanced reactor. Effective voltage thresholds for silicon and thermal SiO 2 etching are observed at −50‐ and −175‐V cathode bias, respectively.

netically enhanced reactive ion etching reactor, including gas pressure, magnetic field, and the gas flow rates of CHF 3 , CF 4 , and Ar. Empirical models of the DC self-bias voltage and etch …

Techniques of cryogenic reactive ion etching in silicon for fabrication of sensors M. David Henrya Department of Applied Physics, California Institute of Technology, Pasadena, California 91125

We used a homemade magnetically enhanced, inductively coupled plasma reactive ion etcher ~ME-ICP-RIE! and electroplated nickel masks. First, 5 h etching experiments using etching gases with 0%, 5%, 10% and 20% oxygen were performed by supplying rf power of 150 and 130 W to an ICP antenna and a sample stage, respectively. They demonstrated a maximum etch rate of 0.45 m m/min and …

Magnetron-enhanced plasma etching process Applied

Magnetically enhanced reactive ion etching of CORE

A method of forming a uniform magnetic field in a modified hexode type etch system is described.Experimental results of etching Si, SiO 2 and photoresist with NF 3 are presented.The magnetic field effectively increases the ion flux and decreases the energy of the ions bombarding the cathode.It was found that adding a magnetic field increases the etchrate of Si for the conditions …

The effectiveness of a curved lateral magnetic field has been examined in magnetically enhanced reactive ion etching (MERIE). It is demonstrated that both charge build-up and etching nonuniformity

A magnetron discharge has been used for high-rate reactive ion etching. A SiO 2 wafer situated on the cathode was etched by scanning a rectangular permanent magnet under the cathode coupled with a power of 13.56 MHz which generated an intense plasma loop over the cathode.

High rate deposition of diamond-like carbon films by magnetically enhanced plasma CVD Z. Sun*, X. Shi, E. Liu School of Electrical & Electronic Engineering, Nanyang Technological University, Singapore 639798, Singapore

Abstract Submicron trench etching of single crystal silicon was studied in a single wafer magnetically enhanced reactive ion etching system. Trenches were etched with both HBr/SiF4/NF3/Iie/02 and HBr/SiF4 etch chemistries.

enhanced, inductively coupled plasma reactive ion etcher ~ME-ICP-RIE! and electroplated nickel masks. First, 5 h etching experiments using etching gases with 0%, 5%, 10% and 20% oxygen were

We used a homemade magnetically enhanced, inductively coupled plasma reactive ion etcher ~ME-ICP-RIE! and electroplated nickel masks. First, 5 h etching experiments using etching gases with 0%, 5%, 10% and 20% oxygen were performed by supplying rf power of 150 and 130 W to an ICP antenna and a sample stage, respectively. They demonstrated a maximum etch rate of 0.45 m m/min and …

D.W. Kim et al. / Thin Solid Films 447–448 (2004) 100–104 101 Fig. 1. Schematic diagram of the magnetically-enhanced inductively coupled plasma etch system used in this study.

Technology Excellence for Specialty Markets (and Etching Basics) Corporate Introduction. Semiconductor Equipment Manufacturing USA manufacturing Focus on high growth specialty markets Lab-to-Fab solutions Multiple production facilities ISO-9000/9001 Plasma-Therm, Florida, USA Advanced Vacuum Lomma, Sweden Rev-Tech, Florida, USA. Relocated to St. Petersburg, FL Plasma-Therm …

• Magnetically Enhanced Reactive Ion Etching plasma sources use transverse static magnetic fields in capacitively coupled discharges for confinement to increase plasma density.

Magnetically Enhanced Reactive Ion Etch (MERIE) Electromagnet (1 of 4) 13.56 MHz Biased wafer chuck Wafer Redrawn from Wet/Dry Etch (College Station, TX: Texas Engineering Extension Service, 1996), p. 165. Figure 16.23. Semiconductor Manufacturing Technology ©2001 by Prentice Hall by Michael Quirk and JulianSerda Dry Etcher Configurations Configurations Activity Pressure (Torr) …

The goal was to develop empirical etch models and determine the process parameters in the etching process using a magnetically enhanced reactive ion etching reactor with CHF3 and O2 gas chemistry. The experimental approach taken uses a 24 factorial design to characterise the relationships between the process factors and etch responses. The factors in the design are: reactor pressure, …

Reactive ion etching of single‐crystal and polycrystalline silicon in bromine has been studied at 2‐mTorr pressure in a magnetically enhanced reactor. Effective voltage thresholds for silicon and thermal SiO 2 etching are observed at −50‐ and −175‐V cathode bias, respectively.

Abstract In Magnetically Enhanced Reactive Ion Etching (MERIE) reactors, a magnetic field parallel to the substrate enables higher plasma densities and control of ion energy distributions.

Magnetically enhanced reactive ion etching of silicon and silicon dioxide . By P. Hoffmann, Y. Mingwen and K.P. Müller. Abstract. The influence of magnetic fields from 0 to 10 mT applied perpendicular to the substrate surface in SF6(CHF3 plasmas was studied for the etching of monocrystalline silicon and silicon dioxide using resist as masking material. A saturation in the …

Fabrication I zumbuhllab.unibas.ch

Fragmentation in magnetically enhanced reactive ion

Abstract Submicron trench etching of single crystal silicon was studied in a single wafer magnetically enhanced reactive ion etching system. Trenches were etched with both HBr/SiF4/NF3/Iie/02 and HBr/SiF4 etch chemistries.

Jpn. J. Appl. Phys. Vol. 39 (2000) pp. 320–323 Part 1, No. 1, January 2000 °c 2000 Publication Board, Japanese Journal of Applied Physics Magnetically Enhanced Reactive Ion Etching of Lead Zirconate Titanate Thin Film

reactions of more than one beam of reactive species with surfaces have received little basic research interest. Yet all these phenomena are involved in present-day plasma-assisted etching technology. This paper, which is an up-dated version of recently published work[1], will discuss some of the more interesting phenomena observed during studies of ion-assisted etching of Si(111) at room

Read “Controlling polymer formation during polysilicon etching in a magnetically enhanced reactive ion etcher, Proceedings of SPIE” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

Etching of the low k SiOCH (BD TM) and SiCH (etch stop) has been investigated in an industrial magnetically enhanced reactive ion etcher (MERIE). XPS on blanket wafers have been performed after partial etching in fluorocarbon based plasmas. During the etch, a steady state fluorocarbon layer (CFx) is present on the film surface, etch rate is governed by the balance of the neutral etchant flow

This study characterizes an oxide etching process in a magnetically enhanced reactive ion etching (MERIE) reactor with a gas chemistry. We use a statistical experimental design plus one center point to characterize the relationships between the process factors and etch responses.

Techniques of cryogenic reactive ion etching in silicon for fabrication of sensors M. David Henrya Department of Applied Physics, California Institute of Technology, Pasadena, California 91125

Reactive ion etchingReactive ion etching ¾ Reactive ion etching is an anisotropic processReactive ion etching is an anisotropic process ! ¾ Has better selectivity and much higher etch rate!

Ar plasma using a magenetically-enhanced reactive ion By etching the oxide film between the metal layer, a via etch system. Etch rate and profile are investigated as a is typically created. In via etching, desired etch features function of process parameters, including radio fre- include high etch rate, high selectivity to the protective quency power, pressure, CHF3 and CF4 flow rates. By

A method of forming a uniform magnetic field in a modified hexode type etch system is described.Experimental results of etching Si, SiO 2 and photoresist with NF 3 are presented.The magnetic field effectively increases the ion flux and decreases the energy of the ions bombarding the cathode.It was found that adding a magnetic field increases the etchrate of Si for the conditions …

Magnetron Enhanced Reactive Ion Etching in a Hexode System

US5607542A Inductively enhanced reactive ion etching

Magnetically Enhanced Reactive Ion Etch (MERIE) Electromagnet (1 of 4) 13.56 MHz Biased wafer chuck Wafer Redrawn from Wet/Dry Etch (College Station, TX: Texas Engineering Extension Service, 1996), p. 165. Figure 16.23. Semiconductor Manufacturing Technology ©2001 by Prentice Hall by Michael Quirk and JulianSerda Dry Etcher Configurations Configurations Activity Pressure (Torr) …

A method of forming a uniform magnetic field in a modified hexode type etch system is described.Experimental results of etching Si, SiO 2 and photoresist with NF 3 are presented.The magnetic field effectively increases the ion flux and decreases the energy of the ions bombarding the cathode.It was found that adding a magnetic field increases the etchrate of Si for the conditions …

In this article the etch characteristics of the DESIRE process in a magnetically enhanced reactive ion etching etcher are described. The application of a magnetic field is shown to increase both the etch rate and the etch selectivity.

Magnetically Enhanced Reactive Ion Etcher (MERIE) – A reactive ion etcher in which a direct current (dc) magnetic field of 50–300 G is applied parallel to the powered electrode on which the wafer sits. The magnetic field increases the plasma density and reduces the sheath voltage. This leads to higher flux of ions and lower bombarding energies. In this respect, MERIE tools are an impro

D.W. Kim et al. / Thin Solid Films 447–448 (2004) 100–104 101 Fig. 1. Schematic diagram of the magnetically-enhanced inductively coupled plasma etch system used in this study.

Oxygen and tetrafluorocarbon magnetically enhanced reactive ion etching (MERIE) of plasma chemical vapor deposited boron nitride (BN) and silicon boron nitride (SiBN) was studied for both blanket and submicron patterned films.

Influence of Etch Process Sequence on CHARM-2 Wafer in

Modeling oxide etching in a magnetically enhanced reactive

Silicon etching in fluorine- and chlorine-containing plasmas 1711 As pressure is decreased below about lOOmTorr, the potential across the discharge characteristically increases, and with this there is a corresponding rise in sheath potentials.

A bare CHARM-2 wafer has been evaluated in a Magnetically Enhanced Reactive Ion Etching (MERIE) apparatus in order to investigate the effect of amagnetic field on the charging phenomena.

The effectiveness of a curved lateral magnetic field has been examined in magnetically enhanced reactive ion etching (MERIE). It is demonstrated that both charge build-up and etching nonuniformity

Magnetically enhanced RIE can aid processing by increasing ion density without increasing ion energy (which can damage the wafer). Ideally, the etch rate is the same (uniform) at all points on a wafer.

D.W. Kim et al. / Thin Solid Films 447–448 (2004) 100–104 101 Fig. 1. Schematic diagram of the magnetically-enhanced inductively coupled plasma etch system used in this study.

A new automatic RIE etching system has been developed. Multi-layers of magnetic materials were fabricated using this system. We compared the process of using conventional Ar gas plasma and the process using CO/NH3 gas plasma. Then by combining the two processes, we achieved smooth surface and good uniformity with a good selectivity to

A magnetron discharge has been used for high-rate reactive ion etching. A SiO 2 wafer situated on the cathode was etched by scanning a rectangular permanent magnet under the cathode coupled with a power of 13.56 MHz which generated an intense plasma loop over the cathode.