Steam and condensate system in paper machine pdf

Steam leaks result in the loss of both latent and sensible energy, while condensate leakage can be the loss of flash steam (latent and sensible energy) or just condensate, which is …

Steam and condensate system design and maintenance The steam and condensate system design is based on the paper sheet weight and the machine configuration by the machine manufacturer. A rotary (left) or stationary (right) syphon All modern syphons require a certain amount of removes condensate from the inside surface of the differential pressure and blowthrough steam to dryer cylinder shell

total steam supply and condensate removal system varies slightly depending on the grade produced. 2621/03/01 EN VALVES FOR TISSUE PAPER MACHINE STEAM SYSTEMS 2 APPLICATION REPORT 12/11 Result Yankee cylinder A tissue machine has a single-cylinder dry end. It is referred to as a Yankee Cylinder. It is a large drum (diameter up to 6 m/19 ft) and the speed of the machine can …

AVACE AACR CE Energy Tips: STEAM Stea i heet Suggested Actions Reduce operating costs through maximizing the return of hot condensate to the boiler. Consider the following actions: If a condensate return system is absent, estimate the cost of a condensate return and treatment system (as necessary) and install one if economically justified. Monitor and repair steam distribution and condensate

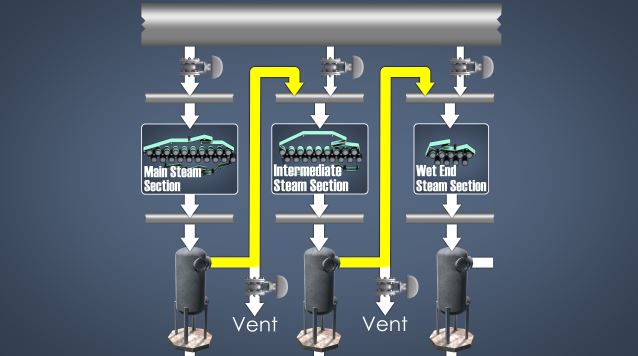

Paper and board machines use steam-heated dryer cylinders to dry the sheet to its final moisture target. In a cascade steam system, fresh steam is typically introduced to the main steam group and then it is cascaded upstream to the intermediate and wet end steam groups.

In today’s business climate, the pulp and paper industry needs suppliers that can offer a comprehensive approach to asset protection and process optimization. The machinery and equipment in operation in pulp and paper mills are highly dependent on the proper control and maintenance of fluids to desired operating conditions. Our approach is simple Asset / Process review and priority setting

It is the purpose of this paper to discuss the considerations of each study item in the context of current market costs, standard design parameters, and an experienced view of operating pitfalls that should be avoided regardless of any cost savings. 1) Sizing of the system The condensate polisher was required to treat a design flow rate of 75 gpm. Specifications developed prior to bidding

Steam and Condensate System Control in Paper Making Slätteke, Ola LU Mark; Abstract The function of a paper machine is to form the paper sheet and remove the water from the sheet.

The dryer section of a paper machine has a potential for large energy losses. In an attempt to better control this source of energy loss, a flow method of controlling blowthru rates was designed

A paper drying system provides steam at the right pressure to every dryer in the machine as per requirement, and ensures an efficient evacuation of condensate from inside the dryers. A good paper drying system facilitates this over the varied paper grades that the machine intends to produce.

The ANDRITZ AUTOMATION PrimeControl provides automation solutions for tissue plants. Our strength is our know-how in process technology, automation and design engineering.

Steam system vent valves Approximately 10% of the paper machines surveyed meet the TAPPI good performance targets for water use per gross ton of production. Machine grades meeting the targets include recycled paperboard, liner, medium, LWC, and pulp. Lowest use observed was 129 gallons per ton in a recycled paperboard mill. Highest use observed was 25,520 gallons per ton on a specialty

27/07/1993 · BACKGROUND OF THE INVENTION. The invention concerns a steam and condensate coupling for a drying cylinder in a paper machine. By means of a steam and condensate coupling for a drying cylinder, a pressure-tight joint is formed between the revolving axle of the drying cylinder and the stationary constructions.

The machines are delivered completely equipped with parts and accessories like central lubrication systems, vacuum systems, steam and condensate systems, Yankee cylinders incl. hoods, QCS and DCS systems, complete MCCs etc.

27/07/2015 · Paper and board machines use steam-heated dryer cylinders to dry the sheet to its final moisture target. In a cascade steam system, fresh steam is used in the main steam …

In a paper machine dryer section, a dryer drum, first means connected to a source of steam under pressure feeding steam into the interior of said drum, second means extending from the interior of said drum receiving steam and condensate from the drum, a separator connected to theV second means to receive steam and condensate and to maintain a condensate level in the separator, a tirst drawot

Issue 19 2013 .95 spiraxsarco.com/au TOPICS

https://youtube.com/watch?v=zye_TAGidD8

Greenhouse Gas Emissions Reduction Fund Proposal

3. STEAM SYSTEM Bureau of Energy Efficiency 55 Syllabus Steam System: Properties of steam, Assessment of steam distribution losses, Steam leak-ages, Steam trapping, Condensate and flash steam recovery system, Identifying opportu-

Install a steam trap condensate collection system on #19 Paper Machine – ,000 5. Install hood economizer on #19 Paper Machine to reuse hot air- 0,000 Total annual savings for these projects is estimated at approximately 0,000 based on an average #6 fuel oil price of .10/gallon. There would be no ongoing operating costs associated with these projects other than the normal monitoring

the steam valve position, the steam pressure, the cylinder temperature, and the paper temperature. The model is based on partial differential equations that describe heat conductivity for the cylinder and the

condensate loop to effectively analyse the behavior of the steam system as a whole. This approach allows a This approach allows a detailed understanding of the interactions between the steam generation, distribution system and the steam-using

Condensate is a significant source of feedwater for steam generation, so good water quality is important. In paper mills, oxygen ingress presents a common yet particularly difficult corrosion problem, resulting in unacceptable condensate quality. In many paper mills, oxygen ingress can occur in paper machines operating under a vacuum or during machine downtime. Uncontrolled, the problem …

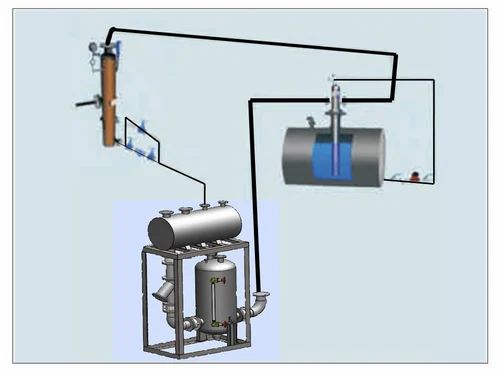

Reiss’ Steam Flash Recovery system has proven to be the most cost effective and efficient method on the market to eliminate waste from the steam condensate recovery system. Steam make-up to the DA, used to heat boiler make up water is significantly reduced. Reiss recently installed their steam flash recovery system to a Tissue Paper Manufacturer in the UK at a capex cost of £117k, with a

4 bypass line was fitted in order to drain the condensate during startups. This line was used for nearly one hour during startup, and as soon as the MG pressure

condensate system design and performance, paper temperature after each dryer, dryer surface temperature as point measurement and pocket air humidity as point measurements.

paper machine consist of: forming section, press section and dryer section. In the forming section, the fibres present in the diluted pulp and water slurry form paper web through drainage by gravity and applied suction below the forming fabric. In the press section additional water in removed by mechanical pressure applied through the nips of a series of presses or rotating rolls and the wet

The steam and condensate system (10) of claim 1 or claim 2, characterized in that a second condensate container unit (56) driven by a device belonging to the second condensate container unit (76), the apparatus (76) comprising a condensate pump and a driving means for driving the condensate …

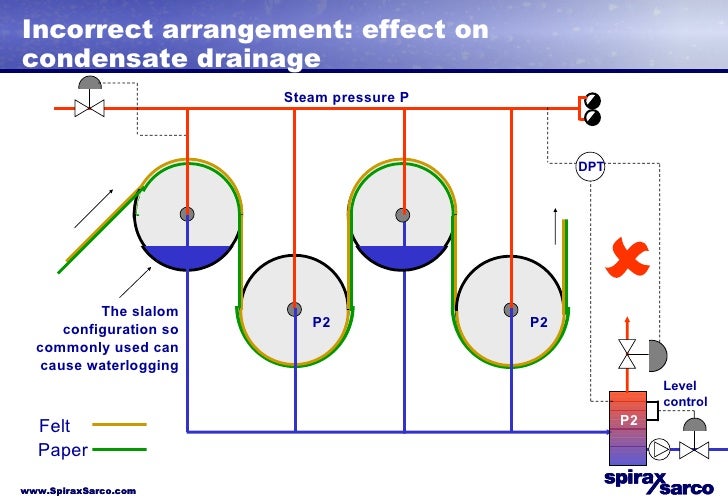

a paper machine steam and condensate system. Drainage of paper machine dryer cylinders is accomplished by controlling the condensate header at a pressure sufficiently less than the steam supply pressure. Differential pressure provides the mechanism for condensate drainage for the dryers. Given sufficient differential pressure, condensate and steam will flow from the dryer cylinders to the …

condensate steam from the dryer because of its close clearance provides non PAPERrimming condensate inside the dryer, even though the speed of the paper machine is also restricted. If a paper machine is “dryer limited” it means that the line speed cannot be increased beyond what the dryer section can dry the wet paper web. Hence by modifying the scoop type rotary siphon into cantilever

Steam traps should be located at all low points and inspected frequently for condensate accumulation. Valves that lack properly positioned steam traps should remain open at all times or be removed from the piping system (for sagging) and the piping insulation (for wear).

CONTROL SYSTEM’S NEW DESIGN REDUCES STEAM AND CONDENSATE LOSSES, WHILE BOOSTING TEXAS MILL’S OUTPUT. Through better control and efficiency, a dryer steam control system’s new design reduces steam and condensate losses, while boosting Texas mill’s output Champion Rebuilds Dryer Steam Controls to Improve Lufkin Machine Performance HEN THE PERFORMANCE of any critical system con- trolling paper

This paper describes a collaborative project to develop an operational expert system prototype that will help mill operators and engineers to troubleshoot and optimize the steam and condensate

Paper Machine Systems . High quality products for manufacturing more paper using less steam. Syphons Wide range of syphons for efficient paper production. Rotary Joints A rotary joint is a device used to supply steam and remove condensate from a rotating dryer Paper Drying Systems Systems which ensure minimum steam consumption during paper drying. Control and Automation in Paper …

dryer section is the largest consumer of steam energy in a paper machine – typically accounting for 55% of the total machine energy cost – an optimized steam and condensate system increases production capability

The EWTP condensate tanks used in the cooling tower water make-up system were available for use in the scheme wherein, with the installation of pipework and pumping facilities condensate can be routed to the required location.

Dryer steam and condensate system rebuilds can be justified based on energy savings, production increases, operational improvement, quality improvement and improved reliability. A factual approach is required to define the opportunity and establish the benefits. The scope of work for the project must be refined to fit within the mill’s financial requirements. Typical steam and condensate

https://youtube.com/watch?v=5GIdxtG8dVI

Thermocompressor Efficiency & Performance Fulton Systems

Strategies in Optimizing Condensate Return By D. Bloom, Sr. Consultant, Ondeo Nalco Company, Naperville, IL Optimizing condensate return for reuse as boiler feedwater is often a viable means of reducing fuel costs and improving boiler system efficiency. Condensate that is contaminated with corrosion products or process chemicals, however, is ill fit for reuse; and steam or condensate that

Real time data (steam demands etc) is sourced from the PI system. Steam Demands Must Be Met Steam is required for the paper machines mainly at 3.4 barg, and mainly at 10.3 barg for the

On a paper machine, drying is accomplished by passing the web around a series of steam-heated cylinders. There are about 40 to 70 dryer cylinders on a typical paper machines, and this is by far the largest part of a papermachine. Drying Page 5 . The dryer cylinders are grouped in sections having 8er -10 dry cylinders. Two such sections are shown in Figure 4. Each section is independently

Steam Theory For Paper Machines Convergence Training

Steam and condensate for paper machines Depending on the thickness of the paper, of the production speed and of the weight of the paper, more than 100 tons of steam per hour are necessary. One ton of steam is about 20 – 25 Euro.

r *X CONFIDENTIAL: MINNESOTA TOBACCO LITIGATION Paper Machine Steam and Condensate Systems Fourth Edition, Revised A PROJECT OF THE WATER REMOVAL COMMITTEE OF THE ENGINEERING…

and condensate system. So before considering any issues such as number of steam groups or use of So before considering any issues such as number of steam groups or use of thermocompressors or cascade, all of the various machine and operating parameters need to be

Steam Piping Design Basics – Welcome to Detail . Both designs use the difference in temperature between live steam and condensate or air to control the release of condensate and air from the steam …

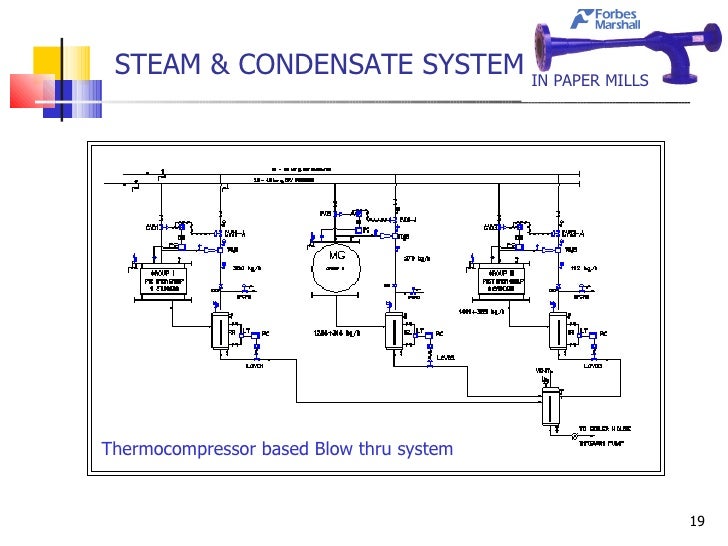

Thermocompressor Efficiency & Performance Abstract A thermocompressor is one of the simplest mechanical devices, yet presents one of the most challenging operational and design selections in a steam and condensate system. This complexity results in the misunderstandings, poor applications, and incorrect operation of a thermocompressor. A thermocompressor’s design should be coordinated …

the steam and knowing which traps meet those requirements while handling the steam condensate. Table 1 summarizes the operating characteristics and suggested applications for …

01 Paper Machine Steam & Condensate Systems.pdf

Steam & Condensate System Audit valmet.com

paper machine – typically accounting for 55% of the total machine energy cost – an optimized steam and condensate system increases production capability and improves machine …

expertise solutions sustainability steam and condensate loop issue volume 4 no 1 news

e Yankee steam and condensate system is a critical part of the drying process. is system must provide a consistent supply of steam to the Yankee cylinder and then remove the condensate that forms. Unfortunately, all system components will experience a degradation in condition and performance over time. Also, even a good condensate removal system doesn’t guarantee optimal performance if …

01 Paper Machine Steam & Condensate Systems.pdf – Download as PDF File (.pdf), Text File (.txt) or read online. Scribd is the world’s largest social reading and publishing site. Search Search

Condensate Groups Steam tank. Uses Ranking Best ood Good Poor oor Poor machine boiler) Unacceptable. t rs Header Header Use In Condensate s House. e electricity electricity • s • t • e • ndition • s • s • m • e eam. e build ory. e. Machine Improved ficiency • poor y • the s – s – es – s – s – ndenser – ems ems. d Paperboard Machine • e – pacity – s

condensate. Real Time TOC Analysis in Steam and Condensate . The Technical Environment Steam (LP up to 15bar – 180°C) is one of the major resources in all chemical and petro-chemical plants. The steam has to be as clean as possible and any contamination of the steam especially from hydrocarbons (TOC) is a clear sign for an accident in the process. Production of steam consumes a lot of

r *X CONFIDENTIAL: MINNESOTA TOBACCO LITIGATION Paper Machine Steam and Condensate Systems Fourth Edition, Revised A PROJECT OF THE WATER REMOVAL COMMITTEE

On a paper or board machine, steam is piped to the inside of each dryer can, where it transfers its heat to the inside surfaces as it condenses into water. When hot condensate is dumped into a receiver at a lower pressure, some of the condensate will “flash” and produce steam.

As one of the leading tissue machine manufacturers, Metso Paper is making great efforts to reduce the energy consumption and increase the energy efficiency of tissue machines.

Paper machine Wikipedia

Steam and Condensate for papermachines Thermodynamik

A paper machine (or paper-making machine) is an industrial machine used in the pulp and paper industry to create paper in large quantities at high speed.

Paper Machine Steam and Condensate Systems 4th Edition, edited by Robert D. Perrault 1990. 40 pp., 8-1/2″ x 11″ soft cover Item Number: 0101R096 ISBN: 0898525047 This book gives papermakers and those responsible for solving drying-related problems a basic understanding of the design, operation, and control of paper machine steam and condensate removal systems. Table of Contents: Foreword

4.1 Steam traps to remove condensate from the steam system must also be purged or they can lead to poor heat transfer and corrosion problems. In order to recover and re-use condensate it is first necessary to remove it from the steam system.

K. Berlin www.dampfundkondensat.de STEAM AND CONDENSATE FOR PAPERMACHINES e e)

25 Fundamentals of Paper Drying Theory and Application from Industrial Perspective Ajit K Ghosh Principal, AKG Process Consulting, 33 McFarlane Court, Highett,

Condensate recovery in industrial systems Addressing water scarcity ENERGY WHITE PAPER 1. EXECUTIVE SUMMARY Steam is a popular and efficient medium for moving heat around a wide variety of processes and premises. Formed by condensed steam, liquid condensate needs to be drained from pipelines and equipment on a continuous basis to avoid the risk of water hammer and to maintain …

The boiler house – a basic overview of a steam system – The boiler is the heart of the steam system. The typical modern packaged boiler is powered by a burner which sends heat into the boiler tubes.

Paper Machine Steam Systems Session 4 Energy Management Seminar , Ho Chi Minh City, May 2008

APPLICATION REPORT 2621/03/02 EN • 12/2011 STEAM AND CONDENSATE SYSTEM Overview of the process The objective of the steam and condensate system in the paper machine is to provide the

PaperAge February 1997 Fulton Systems

Steam and Condensate System Control in Paper Making

Optimising Paper Mill Steam and Electricity Generation

Steam and Condensate A basic overview of a steam system

Closing MG Steam & Condensate System on a Paper Machine

https://youtube.com/watch?v=nL-J5tT1E1k

Steam and energy recovery Reiss Paper Machines

Steam Theory For Paper Machines Convergence Training

Steam & Condensate System Audit valmet.com

Dryer steam and condensate system rebuilds can be justified based on energy savings, production increases, operational improvement, quality improvement and improved reliability. A factual approach is required to define the opportunity and establish the benefits. The scope of work for the project must be refined to fit within the mill’s financial requirements. Typical steam and condensate

the steam valve position, the steam pressure, the cylinder temperature, and the paper temperature. The model is based on partial differential equations that describe heat conductivity for the cylinder and the

Paper Machine Steam Systems Session 4 Energy Management Seminar , Ho Chi Minh City, May 2008

The machines are delivered completely equipped with parts and accessories like central lubrication systems, vacuum systems, steam and condensate systems, Yankee cylinders incl. hoods, QCS and DCS systems, complete MCCs etc.

the steam and knowing which traps meet those requirements while handling the steam condensate. Table 1 summarizes the operating characteristics and suggested applications for …

It is the purpose of this paper to discuss the considerations of each study item in the context of current market costs, standard design parameters, and an experienced view of operating pitfalls that should be avoided regardless of any cost savings. 1) Sizing of the system The condensate polisher was required to treat a design flow rate of 75 gpm. Specifications developed prior to bidding

a paper machine steam and condensate system. Drainage of paper machine dryer cylinders is accomplished by controlling the condensate header at a pressure sufficiently less than the steam supply pressure. Differential pressure provides the mechanism for condensate drainage for the dryers. Given sufficient differential pressure, condensate and steam will flow from the dryer cylinders to the …

27/07/1993 · BACKGROUND OF THE INVENTION. The invention concerns a steam and condensate coupling for a drying cylinder in a paper machine. By means of a steam and condensate coupling for a drying cylinder, a pressure-tight joint is formed between the revolving axle of the drying cylinder and the stationary constructions.

Impss Steaming & Condensate System Clothes Dryer Steam

01 Paper Machine Steam & Condensate Systems.pdf

Paper Machine Systems . High quality products for manufacturing more paper using less steam. Syphons Wide range of syphons for efficient paper production. Rotary Joints A rotary joint is a device used to supply steam and remove condensate from a rotating dryer Paper Drying Systems Systems which ensure minimum steam consumption during paper drying. Control and Automation in Paper …

Steam system vent valves Approximately 10% of the paper machines surveyed meet the TAPPI good performance targets for water use per gross ton of production. Machine grades meeting the targets include recycled paperboard, liner, medium, LWC, and pulp. Lowest use observed was 129 gallons per ton in a recycled paperboard mill. Highest use observed was 25,520 gallons per ton on a specialty

On a paper or board machine, steam is piped to the inside of each dryer can, where it transfers its heat to the inside surfaces as it condenses into water. When hot condensate is dumped into a receiver at a lower pressure, some of the condensate will “flash” and produce steam.

25 Fundamentals of Paper Drying Theory and Application from Industrial Perspective Ajit K Ghosh Principal, AKG Process Consulting, 33 McFarlane Court, Highett,

Real Time TOC Analysis in Steam and Condensate

Paper Drying Systems SEG – Trusted Partners in Steam

A paper drying system provides steam at the right pressure to every dryer in the machine as per requirement, and ensures an efficient evacuation of condensate from inside the dryers. A good paper drying system facilitates this over the varied paper grades that the machine intends to produce.

The steam and condensate system (10) of claim 1 or claim 2, characterized in that a second condensate container unit (56) driven by a device belonging to the second condensate container unit (76), the apparatus (76) comprising a condensate pump and a driving means for driving the condensate …

condensate steam from the dryer because of its close clearance provides non PAPERrimming condensate inside the dryer, even though the speed of the paper machine is also restricted. If a paper machine is “dryer limited” it means that the line speed cannot be increased beyond what the dryer section can dry the wet paper web. Hence by modifying the scoop type rotary siphon into cantilever

condensate system design and performance, paper temperature after each dryer, dryer surface temperature as point measurement and pocket air humidity as point measurements.

In a paper machine dryer section, a dryer drum, first means connected to a source of steam under pressure feeding steam into the interior of said drum, second means extending from the interior of said drum receiving steam and condensate from the drum, a separator connected to theV second means to receive steam and condensate and to maintain a condensate level in the separator, a tirst drawot

27/07/1993 · BACKGROUND OF THE INVENTION. The invention concerns a steam and condensate coupling for a drying cylinder in a paper machine. By means of a steam and condensate coupling for a drying cylinder, a pressure-tight joint is formed between the revolving axle of the drying cylinder and the stationary constructions.

Reiss’ Steam Flash Recovery system has proven to be the most cost effective and efficient method on the market to eliminate waste from the steam condensate recovery system. Steam make-up to the DA, used to heat boiler make up water is significantly reduced. Reiss recently installed their steam flash recovery system to a Tissue Paper Manufacturer in the UK at a capex cost of £117k, with a

Steam and condensate for paper machines Depending on the thickness of the paper, of the production speed and of the weight of the paper, more than 100 tons of steam per hour are necessary. One ton of steam is about 20 – 25 Euro.

Paper Machine Steam and Condensate Systems 4th Edition, edited by Robert D. Perrault 1990. 40 pp., 8-1/2″ x 11″ soft cover Item Number: 0101R096 ISBN: 0898525047 This book gives papermakers and those responsible for solving drying-related problems a basic understanding of the design, operation, and control of paper machine steam and condensate removal systems. Table of Contents: Foreword

In today’s business climate, the pulp and paper industry needs suppliers that can offer a comprehensive approach to asset protection and process optimization. The machinery and equipment in operation in pulp and paper mills are highly dependent on the proper control and maintenance of fluids to desired operating conditions. Our approach is simple Asset / Process review and priority setting

The dryer section of a paper machine has a potential for large energy losses. In an attempt to better control this source of energy loss, a flow method of controlling blowthru rates was designed

Paper Machines Steam and Condensate – Kadant

PaperAge February 1997 Fulton Systems

condensate loop to effectively analyse the behavior of the steam system as a whole. This approach allows a This approach allows a detailed understanding of the interactions between the steam generation, distribution system and the steam-using

The boiler house – a basic overview of a steam system – The boiler is the heart of the steam system. The typical modern packaged boiler is powered by a burner which sends heat into the boiler tubes.

Steam traps should be located at all low points and inspected frequently for condensate accumulation. Valves that lack properly positioned steam traps should remain open at all times or be removed from the piping system (for sagging) and the piping insulation (for wear).

As one of the leading tissue machine manufacturers, Metso Paper is making great efforts to reduce the energy consumption and increase the energy efficiency of tissue machines.

the steam and knowing which traps meet those requirements while handling the steam condensate. Table 1 summarizes the operating characteristics and suggested applications for …

Steam Piping Design Basics – Welcome to Detail . Both designs use the difference in temperature between live steam and condensate or air to control the release of condensate and air from the steam …

e Yankee steam and condensate system is a critical part of the drying process. is system must provide a consistent supply of steam to the Yankee cylinder and then remove the condensate that forms. Unfortunately, all system components will experience a degradation in condition and performance over time. Also, even a good condensate removal system doesn’t guarantee optimal performance if …

27/07/2015 · Paper and board machines use steam-heated dryer cylinders to dry the sheet to its final moisture target. In a cascade steam system, fresh steam is used in the main steam …

The ANDRITZ AUTOMATION PrimeControl provides automation solutions for tissue plants. Our strength is our know-how in process technology, automation and design engineering.

paper machine consist of: forming section, press section and dryer section. In the forming section, the fibres present in the diluted pulp and water slurry form paper web through drainage by gravity and applied suction below the forming fabric. In the press section additional water in removed by mechanical pressure applied through the nips of a series of presses or rotating rolls and the wet

The EWTP condensate tanks used in the cooling tower water make-up system were available for use in the scheme wherein, with the installation of pipework and pumping facilities condensate can be routed to the required location.

4.1 Steam traps to remove condensate from the steam system must also be purged or they can lead to poor heat transfer and corrosion problems. In order to recover and re-use condensate it is first necessary to remove it from the steam system.

Paper Machine Steam Systems Session 4 Energy Management Seminar , Ho Chi Minh City, May 2008

the steam valve position, the steam pressure, the cylinder temperature, and the paper temperature. The model is based on partial differential equations that describe heat conductivity for the cylinder and the

dryer section is the largest consumer of steam energy in a paper machine – typically accounting for 55% of the total machine energy cost – an optimized steam and condensate system increases production capability

CHAMPION REBUILDS DRYER STEAM CONTROLS THROUGH

US2869248A Condensate removal control for paper machine

a paper machine steam and condensate system. Drainage of paper machine dryer cylinders is accomplished by controlling the condensate header at a pressure sufficiently less than the steam supply pressure. Differential pressure provides the mechanism for condensate drainage for the dryers. Given sufficient differential pressure, condensate and steam will flow from the dryer cylinders to the …

Steam and condensate system design and maintenance The steam and condensate system design is based on the paper sheet weight and the machine configuration by the machine manufacturer. A rotary (left) or stationary (right) syphon All modern syphons require a certain amount of removes condensate from the inside surface of the differential pressure and blowthrough steam to dryer cylinder shell

A paper machine (or paper-making machine) is an industrial machine used in the pulp and paper industry to create paper in large quantities at high speed.

Paper Machine Steam Systems Session 4 Energy Management Seminar , Ho Chi Minh City, May 2008

On a paper machine, drying is accomplished by passing the web around a series of steam-heated cylinders. There are about 40 to 70 dryer cylinders on a typical paper machines, and this is by far the largest part of a papermachine. Drying Page 5 . The dryer cylinders are grouped in sections having 8er -10 dry cylinders. Two such sections are shown in Figure 4. Each section is independently

r *X CONFIDENTIAL: MINNESOTA TOBACCO LITIGATION Paper Machine Steam and Condensate Systems Fourth Edition, Revised A PROJECT OF THE WATER REMOVAL COMMITTEE

Paper and board machines use steam-heated dryer cylinders to dry the sheet to its final moisture target. In a cascade steam system, fresh steam is typically introduced to the main steam group and then it is cascaded upstream to the intermediate and wet end steam groups.

K. Berlin www.dampfundkondensat.de STEAM AND CONDENSATE FOR PAPERMACHINES e e)

Condensate recovery in industrial systems Addressing water scarcity ENERGY WHITE PAPER 1. EXECUTIVE SUMMARY Steam is a popular and efficient medium for moving heat around a wide variety of processes and premises. Formed by condensed steam, liquid condensate needs to be drained from pipelines and equipment on a continuous basis to avoid the risk of water hammer and to maintain …

Published October 15 2012 Your Drying Partner valmet.com

Paper Machine Systems SEG – Trusted Partners in Steam

Condensate Groups Steam tank. Uses Ranking Best ood Good Poor oor Poor machine boiler) Unacceptable. t rs Header Header Use In Condensate s House. e electricity electricity • s • t • e • ndition • s • s • m • e eam. e build ory. e. Machine Improved ficiency • poor y • the s – s – es – s – s – ndenser – ems ems. d Paperboard Machine • e – pacity – s

a paper machine steam and condensate system. Drainage of paper machine dryer cylinders is accomplished by controlling the condensate header at a pressure sufficiently less than the steam supply pressure. Differential pressure provides the mechanism for condensate drainage for the dryers. Given sufficient differential pressure, condensate and steam will flow from the dryer cylinders to the …

Paper Machine Systems . High quality products for manufacturing more paper using less steam. Syphons Wide range of syphons for efficient paper production. Rotary Joints A rotary joint is a device used to supply steam and remove condensate from a rotating dryer Paper Drying Systems Systems which ensure minimum steam consumption during paper drying. Control and Automation in Paper …

Thermocompressor Efficiency & Performance Abstract A thermocompressor is one of the simplest mechanical devices, yet presents one of the most challenging operational and design selections in a steam and condensate system. This complexity results in the misunderstandings, poor applications, and incorrect operation of a thermocompressor. A thermocompressor’s design should be coordinated …

Dryer steam and condensate system rebuilds can be justified based on energy savings, production increases, operational improvement, quality improvement and improved reliability. A factual approach is required to define the opportunity and establish the benefits. The scope of work for the project must be refined to fit within the mill’s financial requirements. Typical steam and condensate

r *X CONFIDENTIAL: MINNESOTA TOBACCO LITIGATION Paper Machine Steam and Condensate Systems Fourth Edition, Revised A PROJECT OF THE WATER REMOVAL COMMITTEE OF THE ENGINEERING…

STEAM AND CONDENSATE SYSTEM Documents Metso

Book Paper Machine Steam and Condensate Systems

The machines are delivered completely equipped with parts and accessories like central lubrication systems, vacuum systems, steam and condensate systems, Yankee cylinders incl. hoods, QCS and DCS systems, complete MCCs etc.

APPLICATION REPORT 2621/03/02 EN • 12/2011 STEAM AND CONDENSATE SYSTEM Overview of the process The objective of the steam and condensate system in the paper machine is to provide the

r *X CONFIDENTIAL: MINNESOTA TOBACCO LITIGATION Paper Machine Steam and Condensate Systems Fourth Edition, Revised A PROJECT OF THE WATER REMOVAL COMMITTEE OF THE ENGINEERING…

paper machine – typically accounting for 55% of the total machine energy cost – an optimized steam and condensate system increases production capability and improves machine …

01 Paper Machine Steam & Condensate Systems.pdf – Download as PDF File (.pdf), Text File (.txt) or read online. Scribd is the world’s largest social reading and publishing site. Search Search

Steam and Condensate A basic overview of a steam system

Condensate recovery in industrial systems TAPPSA

The machines are delivered completely equipped with parts and accessories like central lubrication systems, vacuum systems, steam and condensate systems, Yankee cylinders incl. hoods, QCS and DCS systems, complete MCCs etc.

A paper drying system provides steam at the right pressure to every dryer in the machine as per requirement, and ensures an efficient evacuation of condensate from inside the dryers. A good paper drying system facilitates this over the varied paper grades that the machine intends to produce.

Paper Machine Steam and Condensate Systems 4th Edition, edited by Robert D. Perrault 1990. 40 pp., 8-1/2″ x 11″ soft cover Item Number: 0101R096 ISBN: 0898525047 This book gives papermakers and those responsible for solving drying-related problems a basic understanding of the design, operation, and control of paper machine steam and condensate removal systems. Table of Contents: Foreword

Steam and condensate system design and maintenance The steam and condensate system design is based on the paper sheet weight and the machine configuration by the machine manufacturer. A rotary (left) or stationary (right) syphon All modern syphons require a certain amount of removes condensate from the inside surface of the differential pressure and blowthrough steam to dryer cylinder shell

and condensate system. So before considering any issues such as number of steam groups or use of So before considering any issues such as number of steam groups or use of thermocompressors or cascade, all of the various machine and operating parameters need to be

total steam supply and condensate removal system varies slightly depending on the grade produced. 2621/03/01 EN VALVES FOR TISSUE PAPER MACHINE STEAM SYSTEMS 2 APPLICATION REPORT 12/11 Result Yankee cylinder A tissue machine has a single-cylinder dry end. It is referred to as a Yankee Cylinder. It is a large drum (diameter up to 6 m/19 ft) and the speed of the machine can …

e Yankee steam and condensate system is a critical part of the drying process. is system must provide a consistent supply of steam to the Yankee cylinder and then remove the condensate that forms. Unfortunately, all system components will experience a degradation in condition and performance over time. Also, even a good condensate removal system doesn’t guarantee optimal performance if …

The dryer section of a paper machine has a potential for large energy losses. In an attempt to better control this source of energy loss, a flow method of controlling blowthru rates was designed

3. STEAM SYSTEM Bureau of Energy Efficiency 55 Syllabus Steam System: Properties of steam, Assessment of steam distribution losses, Steam leak-ages, Steam trapping, Condensate and flash steam recovery system, Identifying opportu-

condensate loop to effectively analyse the behavior of the steam system as a whole. This approach allows a This approach allows a detailed understanding of the interactions between the steam generation, distribution system and the steam-using

On a paper or board machine, steam is piped to the inside of each dryer can, where it transfers its heat to the inside surfaces as it condenses into water. When hot condensate is dumped into a receiver at a lower pressure, some of the condensate will “flash” and produce steam.

Dryer steam and condensate system rebuilds can be justified based on energy savings, production increases, operational improvement, quality improvement and improved reliability. A factual approach is required to define the opportunity and establish the benefits. The scope of work for the project must be refined to fit within the mill’s financial requirements. Typical steam and condensate

VALVES FOR TISSUE PAPER MACHINE STEAM SYSTEMS

For the Pulp and Paper Industry Industrial Manufacturing

Steam and condensate for paper machines Depending on the thickness of the paper, of the production speed and of the weight of the paper, more than 100 tons of steam per hour are necessary. One ton of steam is about 20 – 25 Euro.

27/07/1993 · BACKGROUND OF THE INVENTION. The invention concerns a steam and condensate coupling for a drying cylinder in a paper machine. By means of a steam and condensate coupling for a drying cylinder, a pressure-tight joint is formed between the revolving axle of the drying cylinder and the stationary constructions.

K. Berlin www.dampfundkondensat.de STEAM AND CONDENSATE FOR PAPERMACHINES e e)

A paper machine (or paper-making machine) is an industrial machine used in the pulp and paper industry to create paper in large quantities at high speed.

On a paper machine, drying is accomplished by passing the web around a series of steam-heated cylinders. There are about 40 to 70 dryer cylinders on a typical paper machines, and this is by far the largest part of a papermachine. Drying Page 5 . The dryer cylinders are grouped in sections having 8er -10 dry cylinders. Two such sections are shown in Figure 4. Each section is independently

As one of the leading tissue machine manufacturers, Metso Paper is making great efforts to reduce the energy consumption and increase the energy efficiency of tissue machines.

4 bypass line was fitted in order to drain the condensate during startups. This line was used for nearly one hour during startup, and as soon as the MG pressure

Condensate is a significant source of feedwater for steam generation, so good water quality is important. In paper mills, oxygen ingress presents a common yet particularly difficult corrosion problem, resulting in unacceptable condensate quality. In many paper mills, oxygen ingress can occur in paper machines operating under a vacuum or during machine downtime. Uncontrolled, the problem …

a paper machine steam and condensate system. Drainage of paper machine dryer cylinders is accomplished by controlling the condensate header at a pressure sufficiently less than the steam supply pressure. Differential pressure provides the mechanism for condensate drainage for the dryers. Given sufficient differential pressure, condensate and steam will flow from the dryer cylinders to the …

Steam and condensate system design and maintenance The steam and condensate system design is based on the paper sheet weight and the machine configuration by the machine manufacturer. A rotary (left) or stationary (right) syphon All modern syphons require a certain amount of removes condensate from the inside surface of the differential pressure and blowthrough steam to dryer cylinder shell

In a paper machine dryer section, a dryer drum, first means connected to a source of steam under pressure feeding steam into the interior of said drum, second means extending from the interior of said drum receiving steam and condensate from the drum, a separator connected to theV second means to receive steam and condensate and to maintain a condensate level in the separator, a tirst drawot

and condensate system. So before considering any issues such as number of steam groups or use of So before considering any issues such as number of steam groups or use of thermocompressors or cascade, all of the various machine and operating parameters need to be

Condensate Recovery System YouTube

01 Paper Machine Steam & Condensate Systems.pdf

K. Berlin www.dampfundkondensat.de STEAM AND CONDENSATE FOR PAPERMACHINES e e)

As one of the leading tissue machine manufacturers, Metso Paper is making great efforts to reduce the energy consumption and increase the energy efficiency of tissue machines.

condensate steam from the dryer because of its close clearance provides non PAPERrimming condensate inside the dryer, even though the speed of the paper machine is also restricted. If a paper machine is “dryer limited” it means that the line speed cannot be increased beyond what the dryer section can dry the wet paper web. Hence by modifying the scoop type rotary siphon into cantilever

condensate loop to effectively analyse the behavior of the steam system as a whole. This approach allows a This approach allows a detailed understanding of the interactions between the steam generation, distribution system and the steam-using

The boiler house – a basic overview of a steam system – The boiler is the heart of the steam system. The typical modern packaged boiler is powered by a burner which sends heat into the boiler tubes.

r *X CONFIDENTIAL: MINNESOTA TOBACCO LITIGATION Paper Machine Steam and Condensate Systems Fourth Edition, Revised A PROJECT OF THE WATER REMOVAL COMMITTEE OF THE ENGINEERING…

The ANDRITZ AUTOMATION PrimeControl provides automation solutions for tissue plants. Our strength is our know-how in process technology, automation and design engineering.

Paper Machine Systems . High quality products for manufacturing more paper using less steam. Syphons Wide range of syphons for efficient paper production. Rotary Joints A rotary joint is a device used to supply steam and remove condensate from a rotating dryer Paper Drying Systems Systems which ensure minimum steam consumption during paper drying. Control and Automation in Paper …

In a paper machine dryer section, a dryer drum, first means connected to a source of steam under pressure feeding steam into the interior of said drum, second means extending from the interior of said drum receiving steam and condensate from the drum, a separator connected to theV second means to receive steam and condensate and to maintain a condensate level in the separator, a tirst drawot

Steam leaks result in the loss of both latent and sensible energy, while condensate leakage can be the loss of flash steam (latent and sensible energy) or just condensate, which is …

Condensate Polisher Savings Of 23% Realized Through Value

Condensate recovery in industrial steam systems Spirax

Steam and condensate for paper machines Depending on the thickness of the paper, of the production speed and of the weight of the paper, more than 100 tons of steam per hour are necessary. One ton of steam is about 20 – 25 Euro.

The ANDRITZ AUTOMATION PrimeControl provides automation solutions for tissue plants. Our strength is our know-how in process technology, automation and design engineering.

Condensate Groups Steam tank. Uses Ranking Best ood Good Poor oor Poor machine boiler) Unacceptable. t rs Header Header Use In Condensate s House. e electricity electricity • s • t • e • ndition • s • s • m • e eam. e build ory. e. Machine Improved ficiency • poor y • the s – s – es – s – s – ndenser – ems ems. d Paperboard Machine • e – pacity – s

3. STEAM SYSTEM Bureau of Energy Efficiency 55 Syllabus Steam System: Properties of steam, Assessment of steam distribution losses, Steam leak-ages, Steam trapping, Condensate and flash steam recovery system, Identifying opportu-

the steam valve position, the steam pressure, the cylinder temperature, and the paper temperature. The model is based on partial differential equations that describe heat conductivity for the cylinder and the

Paper Machine Systems . High quality products for manufacturing more paper using less steam. Syphons Wide range of syphons for efficient paper production. Rotary Joints A rotary joint is a device used to supply steam and remove condensate from a rotating dryer Paper Drying Systems Systems which ensure minimum steam consumption during paper drying. Control and Automation in Paper …

e Yankee steam and condensate system is a critical part of the drying process. is system must provide a consistent supply of steam to the Yankee cylinder and then remove the condensate that forms. Unfortunately, all system components will experience a degradation in condition and performance over time. Also, even a good condensate removal system doesn’t guarantee optimal performance if …

Steam and Condensate System Control in Paper Making Slätteke, Ola LU Mark; Abstract The function of a paper machine is to form the paper sheet and remove the water from the sheet.

The boiler house – a basic overview of a steam system – The boiler is the heart of the steam system. The typical modern packaged boiler is powered by a burner which sends heat into the boiler tubes.

condensate loop to effectively analyse the behavior of the steam system as a whole. This approach allows a This approach allows a detailed understanding of the interactions between the steam generation, distribution system and the steam-using

a paper machine steam and condensate system. Drainage of paper machine dryer cylinders is accomplished by controlling the condensate header at a pressure sufficiently less than the steam supply pressure. Differential pressure provides the mechanism for condensate drainage for the dryers. Given sufficient differential pressure, condensate and steam will flow from the dryer cylinders to the …

In a paper machine dryer section, a dryer drum, first means connected to a source of steam under pressure feeding steam into the interior of said drum, second means extending from the interior of said drum receiving steam and condensate from the drum, a separator connected to theV second means to receive steam and condensate and to maintain a condensate level in the separator, a tirst drawot

Steam system vent valves Approximately 10% of the paper machines surveyed meet the TAPPI good performance targets for water use per gross ton of production. Machine grades meeting the targets include recycled paperboard, liner, medium, LWC, and pulp. Lowest use observed was 129 gallons per ton in a recycled paperboard mill. Highest use observed was 25,520 gallons per ton on a specialty

the steam and knowing which traps meet those requirements while handling the steam condensate. Table 1 summarizes the operating characteristics and suggested applications for …

Paper Machine Systems SEG – Trusted Partners in Steam

Fundamentals of Paper Drying Theory and Application from

AVACE AACR CE Energy Tips: STEAM Stea i heet Suggested Actions Reduce operating costs through maximizing the return of hot condensate to the boiler. Consider the following actions: If a condensate return system is absent, estimate the cost of a condensate return and treatment system (as necessary) and install one if economically justified. Monitor and repair steam distribution and condensate

On a paper or board machine, steam is piped to the inside of each dryer can, where it transfers its heat to the inside surfaces as it condenses into water. When hot condensate is dumped into a receiver at a lower pressure, some of the condensate will “flash” and produce steam.

27/07/2015 · Paper and board machines use steam-heated dryer cylinders to dry the sheet to its final moisture target. In a cascade steam system, fresh steam is used in the main steam …

and condensate system. So before considering any issues such as number of steam groups or use of So before considering any issues such as number of steam groups or use of thermocompressors or cascade, all of the various machine and operating parameters need to be

Steam and condensate for paper machines Depending on the thickness of the paper, of the production speed and of the weight of the paper, more than 100 tons of steam per hour are necessary. One ton of steam is about 20 – 25 Euro.

The ANDRITZ AUTOMATION PrimeControl provides automation solutions for tissue plants. Our strength is our know-how in process technology, automation and design engineering.

APPLICATION REPORT 2621/03/02 EN • 12/2011 STEAM AND CONDENSATE SYSTEM Overview of the process The objective of the steam and condensate system in the paper machine is to provide the

Steam Piping Design Basics – Welcome to Detail . Both designs use the difference in temperature between live steam and condensate or air to control the release of condensate and air from the steam …

4.1 Steam traps to remove condensate from the steam system must also be purged or they can lead to poor heat transfer and corrosion problems. In order to recover and re-use condensate it is first necessary to remove it from the steam system.

total steam supply and condensate removal system varies slightly depending on the grade produced. 2621/03/01 EN VALVES FOR TISSUE PAPER MACHINE STEAM SYSTEMS 2 APPLICATION REPORT 12/11 Result Yankee cylinder A tissue machine has a single-cylinder dry end. It is referred to as a Yankee Cylinder. It is a large drum (diameter up to 6 m/19 ft) and the speed of the machine can …

the steam valve position, the steam pressure, the cylinder temperature, and the paper temperature. The model is based on partial differential equations that describe heat conductivity for the cylinder and the

Issue 19 2013 .95 spiraxsarco.com/au TOPICS

CHAMPION REBUILDS DRYER STEAM CONTROLS THROUGH

25 Fundamentals of Paper Drying Theory and Application from Industrial Perspective Ajit K Ghosh Principal, AKG Process Consulting, 33 McFarlane Court, Highett,

expertise solutions sustainability steam and condensate loop issue volume 4 no 1 news

Steam leaks result in the loss of both latent and sensible energy, while condensate leakage can be the loss of flash steam (latent and sensible energy) or just condensate, which is …

and condensate system. So before considering any issues such as number of steam groups or use of So before considering any issues such as number of steam groups or use of thermocompressors or cascade, all of the various machine and operating parameters need to be

Condensate Groups Steam tank. Uses Ranking Best ood Good Poor oor Poor machine boiler) Unacceptable. t rs Header Header Use In Condensate s House. e electricity electricity • s • t • e • ndition • s • s • m • e eam. e build ory. e. Machine Improved ficiency • poor y • the s – s – es – s – s – ndenser – ems ems. d Paperboard Machine • e – pacity – s

Design and Development of Cantilever Stationary Siphon

For the Pulp and Paper Industry Industrial Manufacturing

Strategies in Optimizing Condensate Return By D. Bloom, Sr. Consultant, Ondeo Nalco Company, Naperville, IL Optimizing condensate return for reuse as boiler feedwater is often a viable means of reducing fuel costs and improving boiler system efficiency. Condensate that is contaminated with corrosion products or process chemicals, however, is ill fit for reuse; and steam or condensate that

On a paper machine, drying is accomplished by passing the web around a series of steam-heated cylinders. There are about 40 to 70 dryer cylinders on a typical paper machines, and this is by far the largest part of a papermachine. Drying Page 5 . The dryer cylinders are grouped in sections having 8er -10 dry cylinders. Two such sections are shown in Figure 4. Each section is independently

Thermocompressor Efficiency & Performance Abstract A thermocompressor is one of the simplest mechanical devices, yet presents one of the most challenging operational and design selections in a steam and condensate system. This complexity results in the misunderstandings, poor applications, and incorrect operation of a thermocompressor. A thermocompressor’s design should be coordinated …

AVACE AACR CE Energy Tips: STEAM Stea i heet Suggested Actions Reduce operating costs through maximizing the return of hot condensate to the boiler. Consider the following actions: If a condensate return system is absent, estimate the cost of a condensate return and treatment system (as necessary) and install one if economically justified. Monitor and repair steam distribution and condensate

Steam and Condensate System Control in Paper Making Slätteke, Ola LU Mark; Abstract The function of a paper machine is to form the paper sheet and remove the water from the sheet.

ROTATING JOINTS AND SIPHON SYSTEMS Deublin

ROTATING JOINTS AND SIPHON SYSTEMS DEUBLIN

A paper drying system provides steam at the right pressure to every dryer in the machine as per requirement, and ensures an efficient evacuation of condensate from inside the dryers. A good paper drying system facilitates this over the varied paper grades that the machine intends to produce.

Steam and condensate system design and maintenance The steam and condensate system design is based on the paper sheet weight and the machine configuration by the machine manufacturer. A rotary (left) or stationary (right) syphon All modern syphons require a certain amount of removes condensate from the inside surface of the differential pressure and blowthrough steam to dryer cylinder shell

CONTROL SYSTEM’S NEW DESIGN REDUCES STEAM AND CONDENSATE LOSSES, WHILE BOOSTING TEXAS MILL’S OUTPUT. Through better control and efficiency, a dryer steam control system’s new design reduces steam and condensate losses, while boosting Texas mill’s output Champion Rebuilds Dryer Steam Controls to Improve Lufkin Machine Performance HEN THE PERFORMANCE of any critical system con- trolling paper

Condensate is a significant source of feedwater for steam generation, so good water quality is important. In paper mills, oxygen ingress presents a common yet particularly difficult corrosion problem, resulting in unacceptable condensate quality. In many paper mills, oxygen ingress can occur in paper machines operating under a vacuum or during machine downtime. Uncontrolled, the problem …

Steam Piping Design Basics – Welcome to Detail . Both designs use the difference in temperature between live steam and condensate or air to control the release of condensate and air from the steam …

25 Fundamentals of Paper Drying Theory and Application from Industrial Perspective Ajit K Ghosh Principal, AKG Process Consulting, 33 McFarlane Court, Highett,

Optimising Paper Mill Steam and Electricity Generation

Design and Development of Cantilever Stationary Siphon

Condensate is a significant source of feedwater for steam generation, so good water quality is important. In paper mills, oxygen ingress presents a common yet particularly difficult corrosion problem, resulting in unacceptable condensate quality. In many paper mills, oxygen ingress can occur in paper machines operating under a vacuum or during machine downtime. Uncontrolled, the problem …

dryer section is the largest consumer of steam energy in a paper machine – typically accounting for 55% of the total machine energy cost – an optimized steam and condensate system increases production capability

01 Paper Machine Steam & Condensate Systems.pdf – Download as PDF File (.pdf), Text File (.txt) or read online. Scribd is the world’s largest social reading and publishing site. Search Search

Install a steam trap condensate collection system on #19 Paper Machine – ,000 5. Install hood economizer on #19 Paper Machine to reuse hot air- 0,000 Total annual savings for these projects is estimated at approximately 0,000 based on an average #6 fuel oil price of .10/gallon. There would be no ongoing operating costs associated with these projects other than the normal monitoring

25 Fundamentals of Paper Drying Theory and Application from Industrial Perspective Ajit K Ghosh Principal, AKG Process Consulting, 33 McFarlane Court, Highett,

Real time data (steam demands etc) is sourced from the PI system. Steam Demands Must Be Met Steam is required for the paper machines mainly at 3.4 barg, and mainly at 10.3 barg for the

CONTROL SYSTEM’S NEW DESIGN REDUCES STEAM AND CONDENSATE LOSSES, WHILE BOOSTING TEXAS MILL’S OUTPUT. Through better control and efficiency, a dryer steam control system’s new design reduces steam and condensate losses, while boosting Texas mill’s output Champion Rebuilds Dryer Steam Controls to Improve Lufkin Machine Performance HEN THE PERFORMANCE of any critical system con- trolling paper

condensate system design and performance, paper temperature after each dryer, dryer surface temperature as point measurement and pocket air humidity as point measurements.

The dryer section of a paper machine has a potential for large energy losses. In an attempt to better control this source of energy loss, a flow method of controlling blowthru rates was designed

NEWS Spirax Sarco International

Condensate Polisher Savings Of 23% Realized Through Value

K. Berlin www.dampfundkondensat.de STEAM AND CONDENSATE FOR PAPERMACHINES e e)

This paper describes a collaborative project to develop an operational expert system prototype that will help mill operators and engineers to troubleshoot and optimize the steam and condensate

Install a steam trap condensate collection system on #19 Paper Machine – ,000 5. Install hood economizer on #19 Paper Machine to reuse hot air- 0,000 Total annual savings for these projects is estimated at approximately 0,000 based on an average #6 fuel oil price of .10/gallon. There would be no ongoing operating costs associated with these projects other than the normal monitoring

AVACE AACR CE Energy Tips: STEAM Stea i heet Suggested Actions Reduce operating costs through maximizing the return of hot condensate to the boiler. Consider the following actions: If a condensate return system is absent, estimate the cost of a condensate return and treatment system (as necessary) and install one if economically justified. Monitor and repair steam distribution and condensate

and condensate system. So before considering any issues such as number of steam groups or use of So before considering any issues such as number of steam groups or use of thermocompressors or cascade, all of the various machine and operating parameters need to be

As one of the leading tissue machine manufacturers, Metso Paper is making great efforts to reduce the energy consumption and increase the energy efficiency of tissue machines.

4 bypass line was fitted in order to drain the condensate during startups. This line was used for nearly one hour during startup, and as soon as the MG pressure

4.1 Steam traps to remove condensate from the steam system must also be purged or they can lead to poor heat transfer and corrosion problems. In order to recover and re-use condensate it is first necessary to remove it from the steam system.

Strategies in Optimizing Condensate Return By D. Bloom, Sr. Consultant, Ondeo Nalco Company, Naperville, IL Optimizing condensate return for reuse as boiler feedwater is often a viable means of reducing fuel costs and improving boiler system efficiency. Condensate that is contaminated with corrosion products or process chemicals, however, is ill fit for reuse; and steam or condensate that

It is the purpose of this paper to discuss the considerations of each study item in the context of current market costs, standard design parameters, and an experienced view of operating pitfalls that should be avoided regardless of any cost savings. 1) Sizing of the system The condensate polisher was required to treat a design flow rate of 75 gpm. Specifications developed prior to bidding

27/07/2015 · Paper and board machines use steam-heated dryer cylinders to dry the sheet to its final moisture target. In a cascade steam system, fresh steam is used in the main steam …

Condensate is a significant source of feedwater for steam generation, so good water quality is important. In paper mills, oxygen ingress presents a common yet particularly difficult corrosion problem, resulting in unacceptable condensate quality. In many paper mills, oxygen ingress can occur in paper machines operating under a vacuum or during machine downtime. Uncontrolled, the problem …

Steam leaks result in the loss of both latent and sensible energy, while condensate leakage can be the loss of flash steam (latent and sensible energy) or just condensate, which is …

VALVES FOR TISSUE PAPER MACHINE STEAM SYSTEMS

Design and Development of Cantilever Stationary Siphon

Paper Machine Systems . High quality products for manufacturing more paper using less steam. Syphons Wide range of syphons for efficient paper production. Rotary Joints A rotary joint is a device used to supply steam and remove condensate from a rotating dryer Paper Drying Systems Systems which ensure minimum steam consumption during paper drying. Control and Automation in Paper …

a paper machine steam and condensate system. Drainage of paper machine dryer cylinders is accomplished by controlling the condensate header at a pressure sufficiently less than the steam supply pressure. Differential pressure provides the mechanism for condensate drainage for the dryers. Given sufficient differential pressure, condensate and steam will flow from the dryer cylinders to the …

Paper Machine Steam and Condensate Systems 4th Edition, edited by Robert D. Perrault 1990. 40 pp., 8-1/2″ x 11″ soft cover Item Number: 0101R096 ISBN: 0898525047 This book gives papermakers and those responsible for solving drying-related problems a basic understanding of the design, operation, and control of paper machine steam and condensate removal systems. Table of Contents: Foreword

Reiss’ Steam Flash Recovery system has proven to be the most cost effective and efficient method on the market to eliminate waste from the steam condensate recovery system. Steam make-up to the DA, used to heat boiler make up water is significantly reduced. Reiss recently installed their steam flash recovery system to a Tissue Paper Manufacturer in the UK at a capex cost of £117k, with a

On a paper machine, drying is accomplished by passing the web around a series of steam-heated cylinders. There are about 40 to 70 dryer cylinders on a typical paper machines, and this is by far the largest part of a papermachine. Drying Page 5 . The dryer cylinders are grouped in sections having 8er -10 dry cylinders. Two such sections are shown in Figure 4. Each section is independently

condensate steam from the dryer because of its close clearance provides non PAPERrimming condensate inside the dryer, even though the speed of the paper machine is also restricted. If a paper machine is “dryer limited” it means that the line speed cannot be increased beyond what the dryer section can dry the wet paper web. Hence by modifying the scoop type rotary siphon into cantilever

Steam Piping Design Basics – Welcome to Detail . Both designs use the difference in temperature between live steam and condensate or air to control the release of condensate and air from the steam …

Improving Dryer Efficiency Ken Hill – Kadant Johnson