Concrete mix design calculations pdf

Fine aggregate content from volumetric calculations concrete mix is not necessarily to produce a concrete of the highest possible quality, but only of adequate quality required for the intended use, consistent with the economics of the project. A reinforced concrete bridge or a building, for example, require concrete of comparatively high strength, whereas in the construction of a dam, a

Concrete Mix Design Calculations – Scribd. Concrete Mix Design Calculations – Download as Text file (.txt), PDF File (.pdf) or view presentation slides online.

Design CF – The actual lbs. (kg) of cement to be used in a CuYd (cu m) of concrete for this design, known as the ‘design cement factor’. % Air – The design volume of air in the mix by percent of the total volume (CuYd or cu m).

To calculate proportion of cement, sand, coarse agrregate and water, It required to do mix design & for this initially it is requird to find out the properties of all ingradients used for

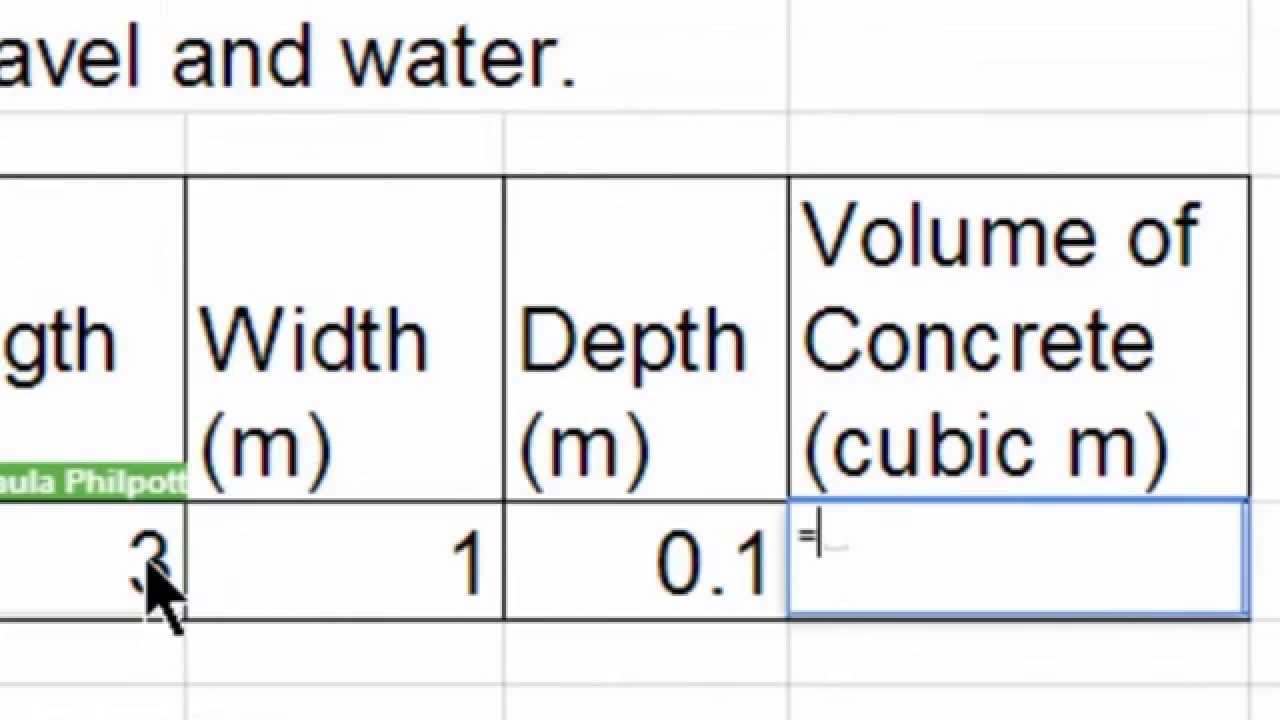

The mix design weights and volumes will now be proportioned on the right side of the grid. If you wish to calculate yield or trial batches, please fill in the “actual density” and “trial batch size (ft3)” cells.

26/07/2018 · concrete mix design calculations pdf concrete mix design is code m15 concrete mix design concrete mix design manual pdf. Category Education; Show more Show less. Loading… Autoplay When autoplay

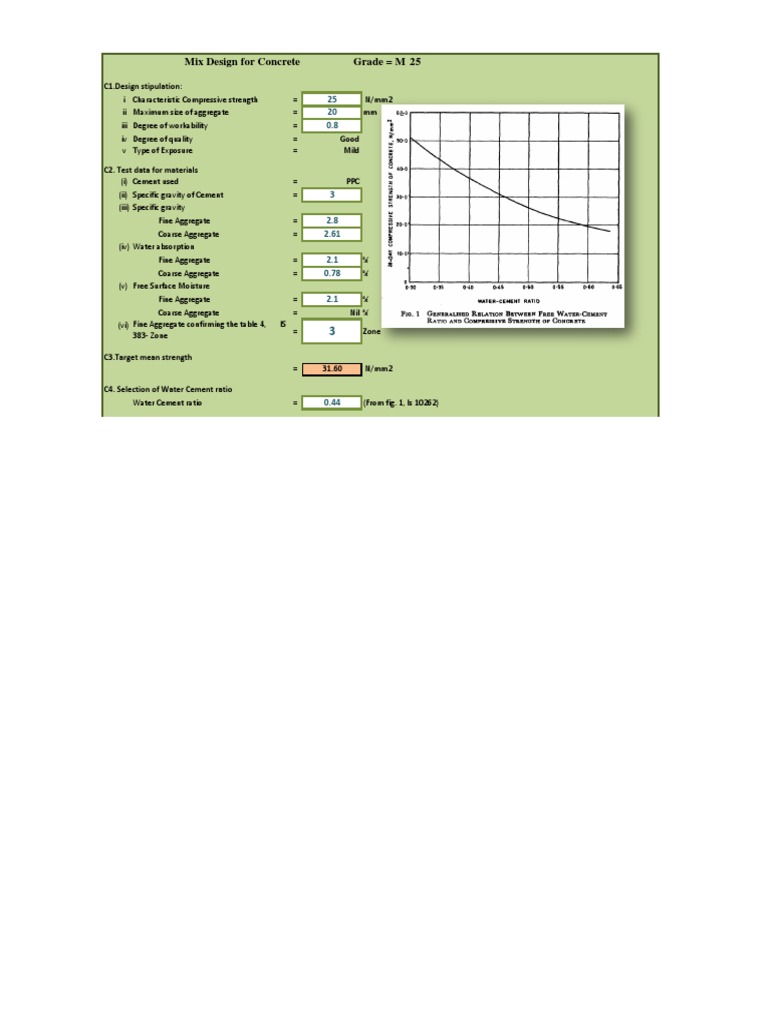

ACI concrete mix design method. ACI recommends a relationship between compressive strength and w/c ratio. Water demands for aggregates sizes are summarised in relation to the concrete workability (consistence) required.

The purpose of this study is investigating the application of DOE concrete mix design method in achieving to a high strength and high performance concrete for a hypothetical tall building constructed near the beach. DOE Method and Calculation Steps DOE method as a kind of concrete mix design method was first established in 1975 and then modified in 1988. It can be applied to concrete for

384 APPENDIX- A Mix Design Procedure of M20 Concrete (Reference Mix) Characteristic Compressive Strength = 20N/mm2 Maximum size of aggregate = 20mm (Angular)

that how design calculations for aggregates content, cement content, and water cement (w/c) ratio are different in these four methods. In accordance with variation in these design procedures, the expected change in properties of concrete (either in fresh stage or in hardened concrete) shall be considered. Properly designed mix for a particular application, keeping in mind the specific

Chapter 5: mix design calculation sheet for 40 N/mm2 concrete mix (28 day strength) A) NA 1-Characteristic strength at 28 days 40 N/mm2

ACI concrete mix design method

https://youtube.com/watch?v=sEAQeKMQEG8

Mix Design Proportioner Concrete Helper- A Concrete

Concrete Mix Design: Mix design is a method which determines the proportions of cement, water, fine aggregates and coarse aggregates to produce the concrete of required strength, workability and durability with minimum cost.

8/05/2017 · Traditional Techniques Craft Skills Construction Plans Available – Building Step Stairs With Brick – Duration: 15:16. Products Construction 454,243 views

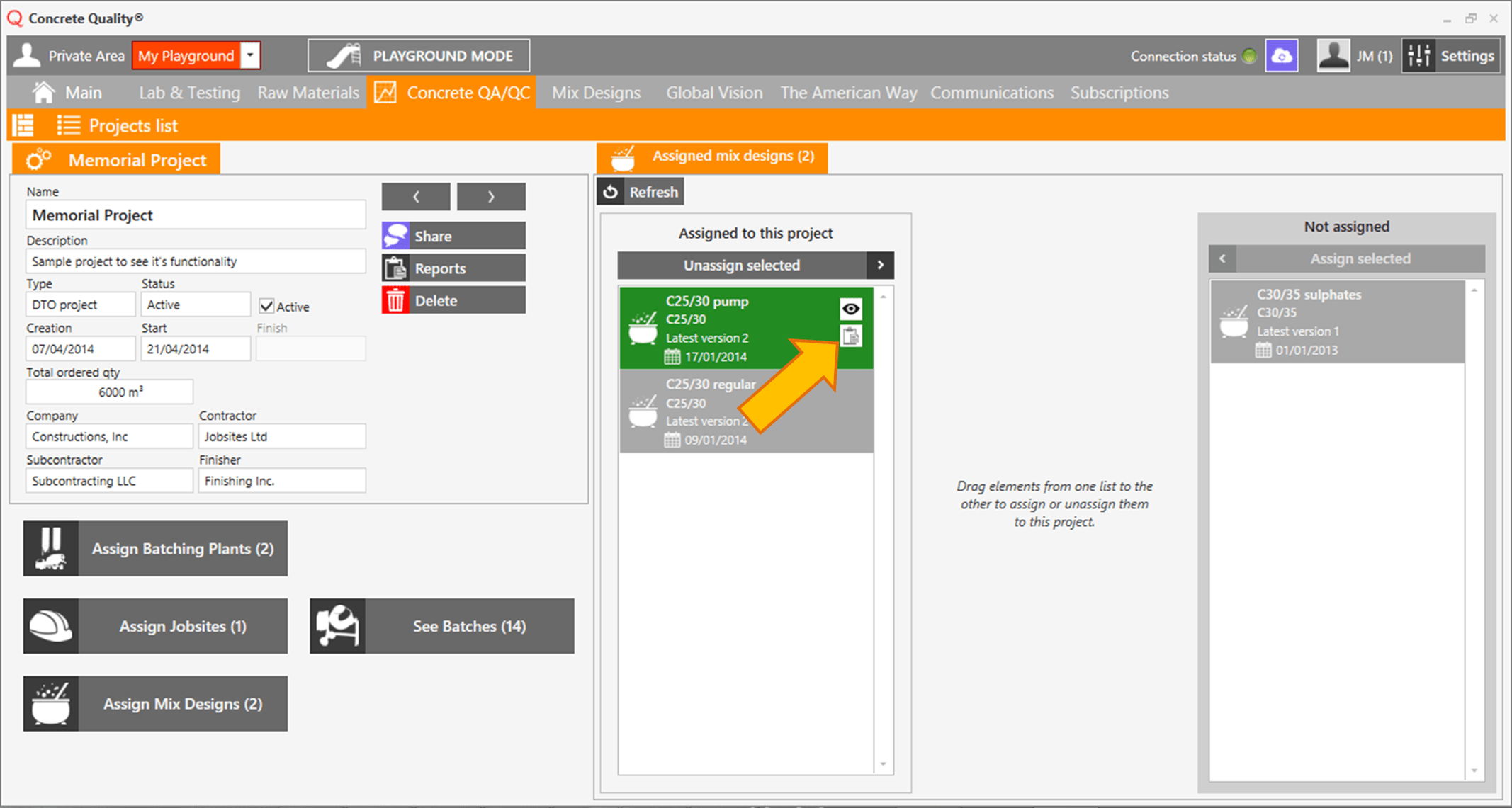

The Step by Step mix design system in Quality Mix guides you throughout the whole mix design process. Select the concrete type you need, the pouring method available in the site, the slump and the ambient conditions at the time of casting.

concrete mix design by dr. b.n. krishnaswami former faculty, dept of civil engg., nit, trichy technical meeting on 09-05-2009 organised by civil engineers & architects…

Calculation of Actual Concrete Shrinkage Magnitude By: Calculation based on a rational procedure as recommended in ACI Committee 29 1]. This is the main topic of this article and by outlining the procedures taken, the reader/s will be guided in how actual shrinkage is calculated which even if complicated is required particularly when the problem blows into a litigation headache. 2] For

Total 60 Chapter 5 Concrete Mix Design Calculations 33 . the resultant value is compared with the density value used during the design. the initial design values should be corrected by the ratio of measured density to assumed density in order to determine the actual masses. In this case.8.8.3 Adjustments to mix proportions (density) • Density After the density of the fresh concrete is measured.

Proceedings Creating with Concrete, May 1999, University of Dundee 1 PACKING CALCULATIONS APPLIED FOR CONCRETE MIX DESIGN M. Glavind E. J. Pedersen

3 MIX DESIGN & PROPORTIONING Mix Design Mixing Proportioning Instructions for Page 1 Of Worksheets Linear Equation of Unit Weight vs. Air Content Instructions for Page 2 of Worksheets Threshold for Max. Allowable Water/Cementitious Ratio Instructions for Page 3 of Worksheets Department Concurrence of Mix Design . 3-1 CHAPTER THREE: MIX DESIGN MIX DESIGN The concrete mix design …

2/12/2015 2 3 Water, Cement, & Aggregate • As the water to cement ratio increases, the strength of a concrete mix decreases. • As the surface area of the a ggregate increases the more

Packing calculations applied for concrete mix design.pdf Information for the Directory of Standards and Technical Regulations Requirements in the Construction Sector 336840647-Volume-Batching-of-Concrete…

Page 1/14 5.10.4 04-10 5.10.4. CALCULATIONS FOR THE MARSHALL MIX DESIGN OF BITUMINOUS MIXTURES 1. Scope. This method covers the formulas used to compute the various values used in the Marshall Mix Design of

2. AGGREGATES Stone and sand for use in concrete should consist of particles of hard material of rounded or roughly cubical shape, with a fairly smooth surface, and

attained by testing of concrete, re-calculations and mix adjustment as deem necessary. This process can be made less cumbersome if the relevant equations are used for mixture proportioning. The interest of this research is to use equations for mix design of structural lightweight concrete rather than the tabular data and graphs in the code to obtain the mix ingredient of structural lightweight

concrete mix design, the procedure involved in this method is described instead of out dated Road Note No 4 method. Step 01: Data to be collected

ACI METHOD OF PROPORTIONING CONCRETE MIXES Selection of water/cement ratio Step 5. Calculation of cement content Step 6. Estimation of coarse aggregate content Step 7. Estimation of Fine Aggregate Content Step 8. Adjustments for Aggregate Moisture Step 9. Trial Batch Adjustments Step 1. Choice of slump If slump is not specified, a value appropriate for the work can be selected …

Total 60 Chapter 5 Concrete Mix Design Calculations 31 . initially.8.3 Adjustments to mix proportions (workability) • Workability During the mixing of the trial mix an experienced technician is able to adjust the water content by inspection if the workability of the mix is much outside the specified range.8. of the mix water until the technician has assessed visually that its addition is

replacement of sand by crusher dust in concrete pdf, , fully replacement of sand by crusher stone dust , Search crusher sand concrete mix design pdf to , [Live Chat] cement process calculations xls – …

Design of Fibre Reinforced Concrete Beams and Slabs Design calculations, regarding moment- and shear resistance in ultimate limit state and crack width calculations in serviceability limit state, were carried out in Mathcad for simply supported beams, with different combinations of ordinary reinforcement and fibre dosages. The design results were then compared with existing experimental

Mix Design Concrete Volume scribd.com

Concrete Mix Design Calculations Concrete Mix Design) pmu l S ( t s a Ct •We • Dry Cast (no Slump)Dry Cast (no Slump) Combination of Art and Science… 1/22/2014 2 3 Water, Cement, & Aggregate • As the water to cement ratio increases, the strength of a concrete mix decreases.concrete mix decreases. • As the surface area of the aggregate increases the more water will be needed to

DEPARTMENT OF CIVIL ENGINEERING, IIT DELHI CEL 774 CONSTRUCTION PRACTISES Mix design of Concrete: IS method B. Bhattacharjee CIVIL ENGINEERING DEPARTMENT

The concrete mix design available on this site are for reference purpose only. Actual site conditions vary and thus this should be adjusted as per the location and other factors.

Investigating the application of DOE method in designing a

concrete Design Calculations Concrete Construction

Quality Mix Concrete Mix Design calculator Concrete Quality

https://youtube.com/watch?v=zNmzS6OOMFA

5.10.4. CALCULATIONS FOR THE MARSHALL MIX DESIGN OF

CONCRETE BASICS FOR BUILDING Lenvalco readymix

Chapter 4 mix design calculation sheet for 40 N/mm2

https://youtube.com/watch?v=CVwdJVuansA

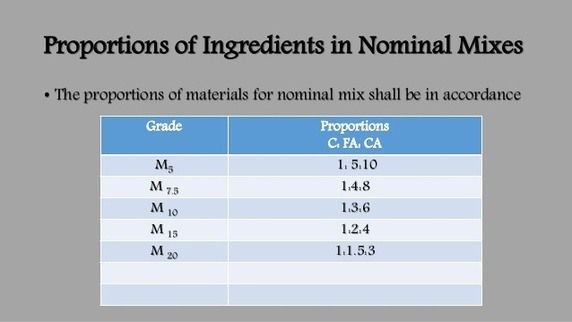

Concrete Mix Design Design Mix Concrete & Nominal Mix

Packing calculations applied for concrete mix design dti.dk

Mix design of Concrete IS method B. Bhattacharjee CIVIL

3 MIX DESIGN & PROPORTIONING Indiana

Concrete Mix Design Calculations Civil Engineering

Quality Mix Concrete Mix Design calculator Concrete Quality

Mix Design Concrete Volume scribd.com

that how design calculations for aggregates content, cement content, and water cement (w/c) ratio are different in these four methods. In accordance with variation in these design procedures, the expected change in properties of concrete (either in fresh stage or in hardened concrete) shall be considered. Properly designed mix for a particular application, keeping in mind the specific

2. AGGREGATES Stone and sand for use in concrete should consist of particles of hard material of rounded or roughly cubical shape, with a fairly smooth surface, and

concrete mix design, the procedure involved in this method is described instead of out dated Road Note No 4 method. Step 01: Data to be collected

3 MIX DESIGN & PROPORTIONING Mix Design Mixing Proportioning Instructions for Page 1 Of Worksheets Linear Equation of Unit Weight vs. Air Content Instructions for Page 2 of Worksheets Threshold for Max. Allowable Water/Cementitious Ratio Instructions for Page 3 of Worksheets Department Concurrence of Mix Design . 3-1 CHAPTER THREE: MIX DESIGN MIX DESIGN The concrete mix design …

Packing calculations applied for concrete mix design.pdf Information for the Directory of Standards and Technical Regulations Requirements in the Construction Sector 336840647-Volume-Batching-of-Concrete…

Concrete Mix Design Calculations – Scribd. Concrete Mix Design Calculations – Download as Text file (.txt), PDF File (.pdf) or view presentation slides online.

Total 60 Chapter 5 Concrete Mix Design Calculations 33 . the resultant value is compared with the density value used during the design. the initial design values should be corrected by the ratio of measured density to assumed density in order to determine the actual masses. In this case.8.8.3 Adjustments to mix proportions (density) • Density After the density of the fresh concrete is measured.

Chapter 5: mix design calculation sheet for 40 N/mm2 concrete mix (28 day strength) A) NA 1-Characteristic strength at 28 days 40 N/mm2

26/07/2018 · concrete mix design calculations pdf concrete mix design is code m15 concrete mix design concrete mix design manual pdf. Category Education; Show more Show less. Loading… Autoplay When autoplay

Proceedings Creating with Concrete, May 1999, University of Dundee 1 PACKING CALCULATIONS APPLIED FOR CONCRETE MIX DESIGN M. Glavind E. J. Pedersen

ACI METHOD OF PROPORTIONING CONCRETE MIXES Selection of water/cement ratio Step 5. Calculation of cement content Step 6. Estimation of coarse aggregate content Step 7. Estimation of Fine Aggregate Content Step 8. Adjustments for Aggregate Moisture Step 9. Trial Batch Adjustments Step 1. Choice of slump If slump is not specified, a value appropriate for the work can be selected …

concrete mix design by dr. b.n. krishnaswami former faculty, dept of civil engg., nit, trichy technical meeting on 09-05-2009 organised by civil engineers & architects…

replacement of sand by crusher dust in concrete pdf, , fully replacement of sand by crusher stone dust , Search crusher sand concrete mix design pdf to , [Live Chat] cement process calculations xls – …

Page 1/14 5.10.4 04-10 5.10.4. CALCULATIONS FOR THE MARSHALL MIX DESIGN OF BITUMINOUS MIXTURES 1. Scope. This method covers the formulas used to compute the various values used in the Marshall Mix Design of

attained by testing of concrete, re-calculations and mix adjustment as deem necessary. This process can be made less cumbersome if the relevant equations are used for mixture proportioning. The interest of this research is to use equations for mix design of structural lightweight concrete rather than the tabular data and graphs in the code to obtain the mix ingredient of structural lightweight

Concrete Mix Design Calculations [PDF Document]

Chapter 4 mix design calculation sheet for 40 N/mm2

8/05/2017 · Traditional Techniques Craft Skills Construction Plans Available – Building Step Stairs With Brick – Duration: 15:16. Products Construction 454,243 views

Concrete Mix Design Calculations – Scribd. Concrete Mix Design Calculations – Download as Text file (.txt), PDF File (.pdf) or view presentation slides online.

Design CF – The actual lbs. (kg) of cement to be used in a CuYd (cu m) of concrete for this design, known as the ‘design cement factor’. % Air – The design volume of air in the mix by percent of the total volume (CuYd or cu m).

attained by testing of concrete, re-calculations and mix adjustment as deem necessary. This process can be made less cumbersome if the relevant equations are used for mixture proportioning. The interest of this research is to use equations for mix design of structural lightweight concrete rather than the tabular data and graphs in the code to obtain the mix ingredient of structural lightweight

Concrete Mix Design Calculations Concrete Mix Design) pmu l S ( t s a Ct •We • Dry Cast (no Slump)Dry Cast (no Slump) Combination of Art and Science… 1/22/2014 2 3 Water, Cement, & Aggregate • As the water to cement ratio increases, the strength of a concrete mix decreases.concrete mix decreases. • As the surface area of the aggregate increases the more water will be needed to

The purpose of this study is investigating the application of DOE concrete mix design method in achieving to a high strength and high performance concrete for a hypothetical tall building constructed near the beach. DOE Method and Calculation Steps DOE method as a kind of concrete mix design method was first established in 1975 and then modified in 1988. It can be applied to concrete for

that how design calculations for aggregates content, cement content, and water cement (w/c) ratio are different in these four methods. In accordance with variation in these design procedures, the expected change in properties of concrete (either in fresh stage or in hardened concrete) shall be considered. Properly designed mix for a particular application, keeping in mind the specific

Total 60 Chapter 5 Concrete Mix Design Calculations 31 . initially.8.3 Adjustments to mix proportions (workability) • Workability During the mixing of the trial mix an experienced technician is able to adjust the water content by inspection if the workability of the mix is much outside the specified range.8. of the mix water until the technician has assessed visually that its addition is

2. AGGREGATES Stone and sand for use in concrete should consist of particles of hard material of rounded or roughly cubical shape, with a fairly smooth surface, and

2/12/2015 2 3 Water, Cement, & Aggregate • As the water to cement ratio increases, the strength of a concrete mix decreases. • As the surface area of the a ggregate increases the more

26/07/2018 · concrete mix design calculations pdf concrete mix design is code m15 concrete mix design concrete mix design manual pdf. Category Education; Show more Show less. Loading… Autoplay When autoplay

ACI concrete mix design method. ACI recommends a relationship between compressive strength and w/c ratio. Water demands for aggregates sizes are summarised in relation to the concrete workability (consistence) required.

Mix Design Proportioner Concrete Helper- A Concrete

Packing calculations applied for concrete mix design dti.dk

To calculate proportion of cement, sand, coarse agrregate and water, It required to do mix design & for this initially it is requird to find out the properties of all ingradients used for

The concrete mix design available on this site are for reference purpose only. Actual site conditions vary and thus this should be adjusted as per the location and other factors.

26/07/2018 · concrete mix design calculations pdf concrete mix design is code m15 concrete mix design concrete mix design manual pdf. Category Education; Show more Show less. Loading… Autoplay When autoplay

replacement of sand by crusher dust in concrete pdf, , fully replacement of sand by crusher stone dust , Search crusher sand concrete mix design pdf to , [Live Chat] cement process calculations xls – …

ACI METHOD OF PROPORTIONING CONCRETE MIXES Selection of water/cement ratio Step 5. Calculation of cement content Step 6. Estimation of coarse aggregate content Step 7. Estimation of Fine Aggregate Content Step 8. Adjustments for Aggregate Moisture Step 9. Trial Batch Adjustments Step 1. Choice of slump If slump is not specified, a value appropriate for the work can be selected …

Concrete Mix Design: Mix design is a method which determines the proportions of cement, water, fine aggregates and coarse aggregates to produce the concrete of required strength, workability and durability with minimum cost.

384 APPENDIX- A Mix Design Procedure of M20 Concrete (Reference Mix) Characteristic Compressive Strength = 20N/mm2 Maximum size of aggregate = 20mm (Angular)

Concrete Mix Design Calculations – Scribd. Concrete Mix Design Calculations – Download as Text file (.txt), PDF File (.pdf) or view presentation slides online.

Packing calculations applied for concrete mix design.pdf Information for the Directory of Standards and Technical Regulations Requirements in the Construction Sector 336840647-Volume-Batching-of-Concrete…

3 MIX DESIGN & PROPORTIONING Mix Design Mixing Proportioning Instructions for Page 1 Of Worksheets Linear Equation of Unit Weight vs. Air Content Instructions for Page 2 of Worksheets Threshold for Max. Allowable Water/Cementitious Ratio Instructions for Page 3 of Worksheets Department Concurrence of Mix Design . 3-1 CHAPTER THREE: MIX DESIGN MIX DESIGN The concrete mix design …

Calculation of Actual Concrete Shrinkage Magnitude By: Calculation based on a rational procedure as recommended in ACI Committee 29 1]. This is the main topic of this article and by outlining the procedures taken, the reader/s will be guided in how actual shrinkage is calculated which even if complicated is required particularly when the problem blows into a litigation headache. 2] For

Page 1/14 5.10.4 04-10 5.10.4. CALCULATIONS FOR THE MARSHALL MIX DESIGN OF BITUMINOUS MIXTURES 1. Scope. This method covers the formulas used to compute the various values used in the Marshall Mix Design of

DEPARTMENT OF CIVIL ENGINEERING, IIT DELHI CEL 774 CONSTRUCTION PRACTISES Mix design of Concrete: IS method B. Bhattacharjee CIVIL ENGINEERING DEPARTMENT

Total 60 Chapter 5 Concrete Mix Design Calculations 31 . initially.8.3 Adjustments to mix proportions (workability) • Workability During the mixing of the trial mix an experienced technician is able to adjust the water content by inspection if the workability of the mix is much outside the specified range.8. of the mix water until the technician has assessed visually that its addition is

Concrete Mix Design: Mix design is a method which determines the proportions of cement, water, fine aggregates and coarse aggregates to produce the concrete of required strength, workability and durability with minimum cost.

Mix design of Concrete IS method B. Bhattacharjee CIVIL